China Manufacturers Custom OEM Hardware Metal Stamping Parts Fabrication Service

§. Our Advantages: ⊙ Can provide extremely competitive prices⊙ 27 years of professional hardware processing experience⊙

Basic Info

| Model NO. | LA-MST061 |

| Processing Type | Deep Drawing |

| Material | Stainless Steel |

| Mould | Multistep Progressive Dies |

| Surface Processing | Electroplating |

| Fine Blanking | Open |

| Process | Forming Process |

| Industry | Auto Accessories |

| Tolerances | 0.02mm |

| Customized | Customized |

| Testing Equipment | CMM Testing Machine |

| Production Equipment | Stamping Machine, Press Machine, Laser Cutting |

| Quality Management System Certification | ISO 9001 |

| Auto Quality Management System Certifica | IATF16949:2016 |

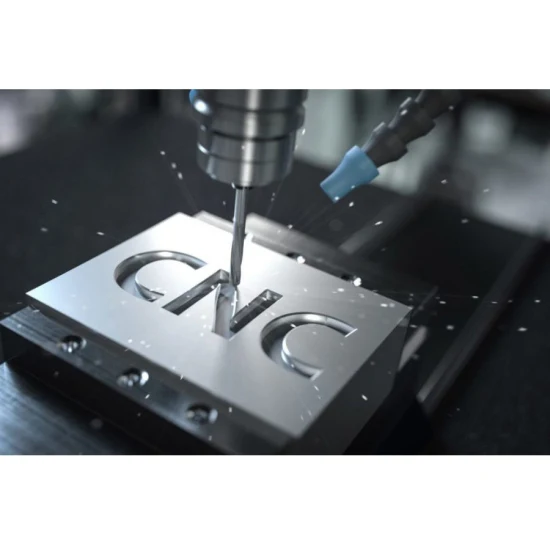

| Main Processes | Stamping,Laser Welding&Cutting,Robot,CNC |

| Transport Package | Carton or Wooden Box or Customized |

| Specification | Based on drawings & customized |

| Trademark | LA |

| Origin | China Cangzhou City |

| HS Code | 7326909090 |

| Production Capacity | 60000 Pieces/Month |

Product Description

| Cangzhou Ling Ang Hardware Manufacturing (LA) | |

| LA has the ability to provide various of metal fabrication parts, our production process is mature and well-equipped,We are a preeminent hardware processing and supply company that has established good relationships with customers worldwide. | |

§. Our Advantages:

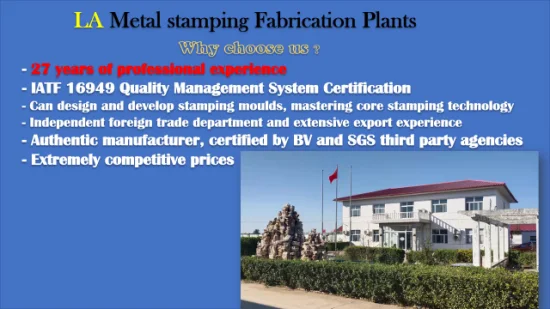

⊙ Can provide extremely competitive prices⊙ 27 years of professional hardware processing experience⊙ Authentic manufacturer, dual Certification by BV and SGS agencies⊙ Independent foreign trade department and extensive export experience ⊙ Can design and develop stamping moulds, mastering core stamping technology⊙ Implementing IATF 16949 Quality Management System Certification(More stringent than ISO 9001)

§§. Hardware Product Development Capabilities: The vast majority of our molds are designed and developed in-house. By identifying machining defects in advance during the mold design stage, we can shorten the development cycle and maximize the product qualification rate.Accuracy can be guaranteed while ensuring consistency and stability of the products.

§§§. Product Quality & Customer Satisfaction Assurance System: Our company strictly implements the world-wide common IATF 16949 quality management system and implements strict quality control on the production process and before the products leave the factory.Product dimensions, structural position dimensions and product appearance during the manufacturing process are checked and controlled in strict accordance with design standards or special customer requirements.

The IATF 16949 system continuously requires LA to achieve satisfaction and win-win with customers:1. Focus on customer satisfaction2. Reduce costs and increase efficiency3. Improving product and delivery quality

§§§§. Main Production and Testing Equipments:

| Production Equitment Name | Specification | Qty | Manufacture |

| Punching machine | 400T | 2 | XUDUAN |

| Punching machine | 350T | 1 | YANGLI |

| Punching machine | 200T | 2 | XUDUAN |

| Punching machine | 160T | 4 | YANGLI,OUTAI |

| Punching machine | 80T | 12 | YANGLI |

| Punching machine | 63T | 12 | WODE |

| Punching machine | 40T | 20 | JINAN |

| Laser cutting | HSG76CT4 | 2 | HSG |

| Laser welding robot | ABB | 2 | ABB/Switzerland |

| Carbon dioxide shielded welding robot | FD11 | 2 | OTC JAPAN/ABB |

| Numerical control lathe | HZFE26 | 3 | HANGZHOU |

| Nc drilling machine | MS58 | 4 | SHANDONG |

| CNC punching machine | JHD-A5 | 1 | JIANGSU |

| CNC bending machine | 100T | 1 | SHANGHAI |

| CNC shearing machine | 6.3X2000 | 2 | JILIN |

Please feel free to contact us, we guarantee to provide professional service and quality products.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

FAQ:

Q:what is the delivery time of the sheet metal fabrication parts?

A:Tooling delivery time is about 20-35 days , the mass production delivery time will see the quantity and the product complication.

Q:What is the development workflow for metal stampings?

A: First step , the customer need to provide drawing to make the tooling, then produce sample for the customer to test. when the customer confirm the quality and details without any issue, then the bulk production will be arranged.

Q:How to ensure the metal stamping products quality?

A: We rely on the IATF 16949 quality management system for quality control,we strictly enforce process control,and QA,QC engineer has related experience over many years.

Send to us