Customized Precision Stainless Steel Aluminum Titanium CNC Machining Milling Turning Parts Fabrication CNC Machining Parts Service

Basic Info

| HS Code | 73269019 |

Product Description

| Item | Customized Precision CNC Machining Parts |

| Material | 1.Stainless Steel Alloy: 303 / 304 / 316 / 412 / etc. Other Special Materials: Lucite / Nylon / Bakelite / POM / ABS / PP / PC / PE / PEEK / Titanium etc. |

| Surface treament | Anodize, Plating, Brushing, Polishing, Blackened, Powder coating, Sandblasting, Laser engraving etc. |

| Tolerance | ±0.08mm |

| Equipment | CNC centre,CNC lathe,General lathe,General Milling, CNC milling, Drilling machine, internal grinder.Cylindrical grinder machine,centerless grinder machine & other equipments. |

| Standard | Our factory are specialized in the production of Non-standard products. |

We also could produce standard products | |

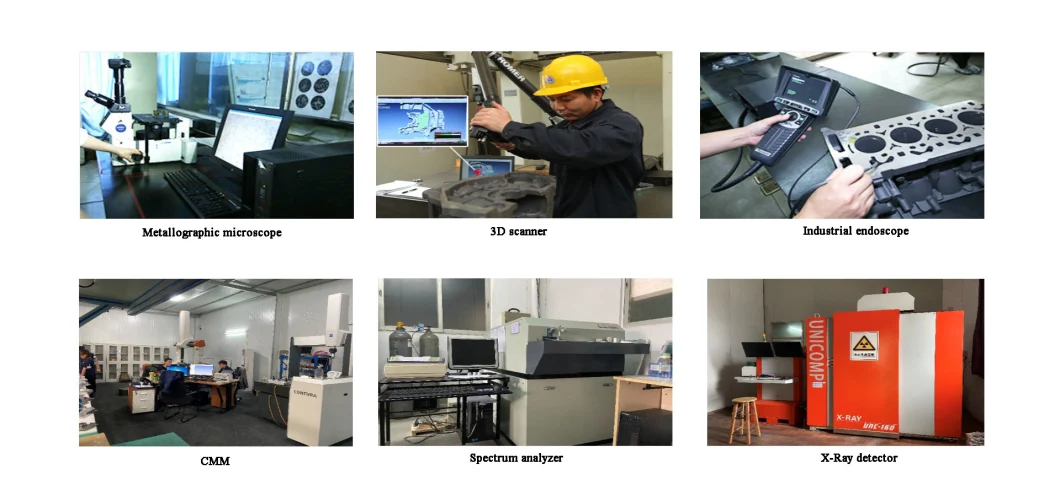

| Inspection tool | Micrometer, Thread Gages,Calipers,Pin Gauge,Projector,CMM, Altimeter etc |

| Quality control | 1. Quality control :The defective products rate is 0.1%. Imported material 100%.2. Reasonable price , Precision made.Experience & Reasonable QC that you can reply on.3. Each part would be given 100% test and tryout before shipment.4. Adequate supply capacity. Punctual delivery time.5. Machining allowance ±0.01mm. |

Why work with FHZL?FHZL brand and reputation:

The national High-tech Enterprise in China;

The foundry Industry Association in Guangdong Province;

The 5A Association of Automobile Industry in Foshan City;

The listed company on stock market(stock code:834914).

Strict quality control system:

Included incoming inspection, sample inspection, process inspection and delivery inspection.

IFAT 16949 certificate, CE certificate and ISO 14001 and ISO 9001 certificated factory.

Lower cost and shortened delivery time:

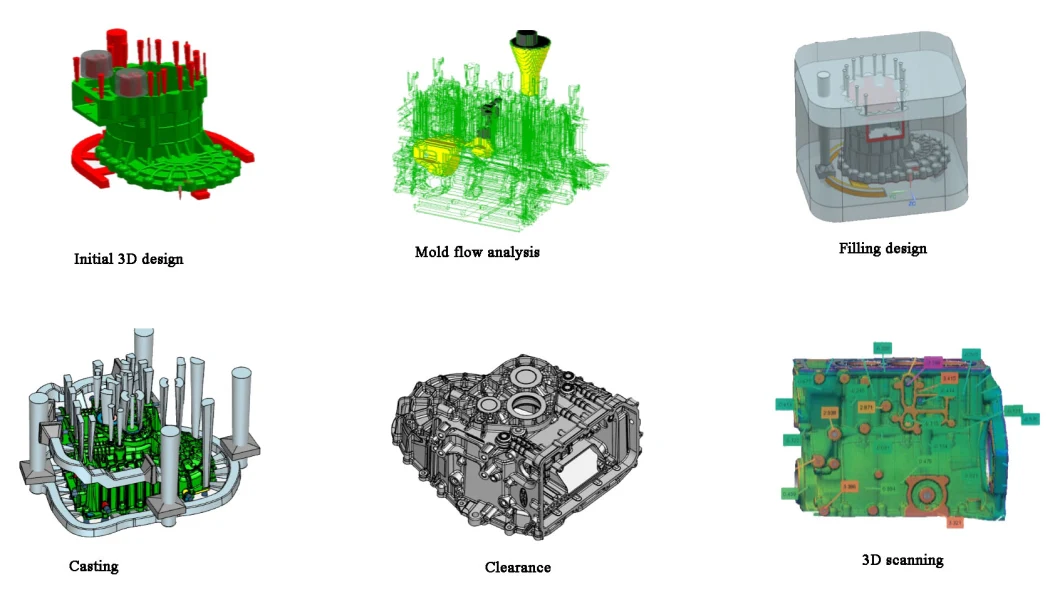

patented new technology PCM (patternless casting manufacturing) has been applied to our manufacturing which improved the traditional casting efficiency rapidly.

No need of mold, casting pattern be formed one time, save the mold cost and mold making time.

More flexible during process:

In case of any failure on the design, PCM technology just need to modify the 3D drawings and restart, no mold modification cost.

What's the technical process for casting?

High precision CNC machines and inspection devices.

(1) Competitive price, all products are casted and machined in our factory, shipped directly to customer.(2) Reliable quality, IATF16946 certified casting manufacturer, we have strict control about quality.(3) Professional, we focus on production of Auto Parts for more than ten years.(4) Fast shipment, we have a efficient management system, several automatic casting lines, and more than ten machining lines.(5) Excellent service, our sales team has more than ten years' experience in oversea market, we know you better.(6) Flexible production, we can customize the product according to your drawing.

1. Are you a factory or trading company? We are a IATF16949 certified factory specializing in producing Auto parts. We cast and machine the parts for more than ten years.2. Can you customize the parts according to the drawing?We have professional technical dept., we are able to customize your parts according to the drawings.3. Can you supply samples?We can supply the samples, but you need to bear the development and delivery cost.4. Do you have a min order quantity?We don't have a min order quantity, we can send you the parts according to your drawings5. What is the period of sample production?It will take 15~25 days to develop new product.