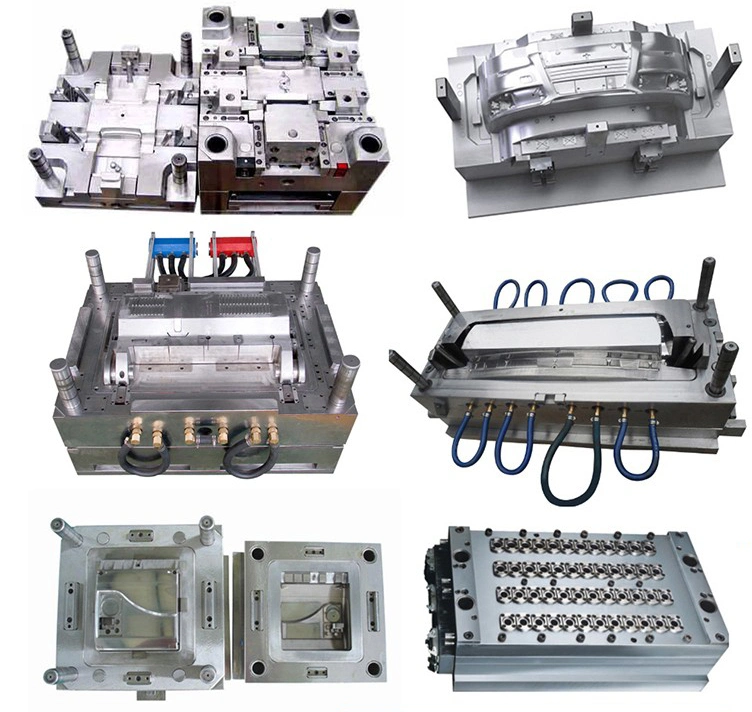

Design and Manufacturing Custom Injection Molding Part China Plastic Mold Maker

Basic Info

| Model NO. | IP227 |

| Runner | Hot Runner |

| Design Software | AutoCAD |

| Installation | Fixed |

| Certification | TS16949, CE, ISO |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | 1 Year |

| Quality Assurance | Design Control, Steel Hardness Inspection Report |

| Cooling | Baffles/Sprin Piple/3D Printing Water Line |

| Standard Delivery | 30 Days or 4 Weeks |

| Tolerance Request | +-0.01mm |

| Transport Package | Carton |

| Trademark | Ideal Pro |

| Origin | Zhejiang |

| HS Code | 848071009 |

| Production Capacity | 5000 Sets/Month |

Product Description

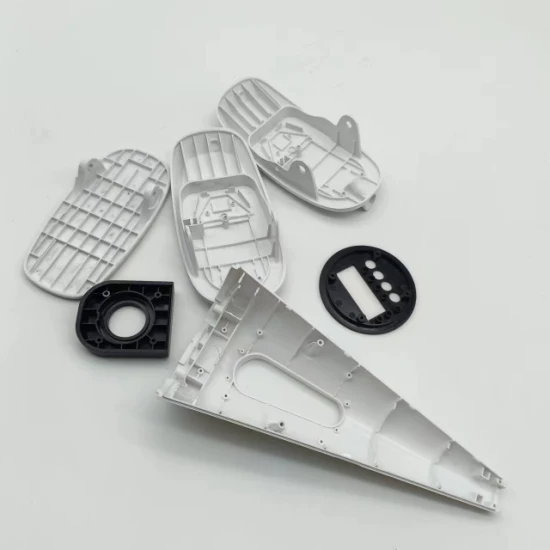

| Product Description | OEM ODM plastic injection molding |

| Plastic Materials | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc. |

| Standard | ISO9001:2008 |

| Quality | RoSH and SGS standard |

| Feature | Non marking and Non flash |

| Size | According to your 2D, 3D Drawing |

| Color,Quantity,Unit price,Tooling cost,Tooling size | To be discussed |

| Package | Standard exported Wooden box packed, Fumigation process(upon required) |

| Mold Building Lead Time | 20~30 working days, Part measurement report (upon required). |

| Export Country | Europe, Japan, America, Australian, UK, Canada, France, Germany, Italy...etc.: |

| To be discussed | In-Mold Decoration, Injection Mould, Plastic Mold, Overmould, 2K Mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold,Collapsible Core Mold, Die Sets, Compression Mold, Cold Runner System LSR Mold,...etc. |

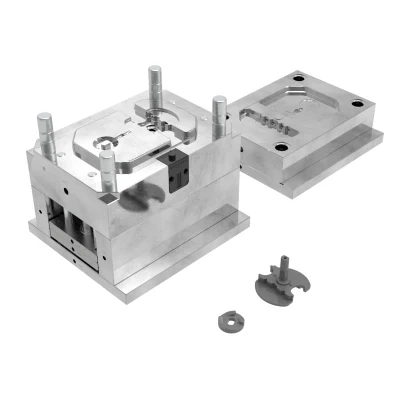

| Mould Base | Hasco Standard, European Standard, World Standard |

| Mould Base Material | LKM, FUTA, HASCO, DME,...etc. Or as per Customer's Requirment |

| Surface Finish | Texture(MT standard), High gloss polishing |

| Cavity/Core Steel | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 ...etc. |

| Mould Life | 250,000 to 500,000 Shots. (According to your working environment.) |

| Design & Program Softwares | CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA....etc. |

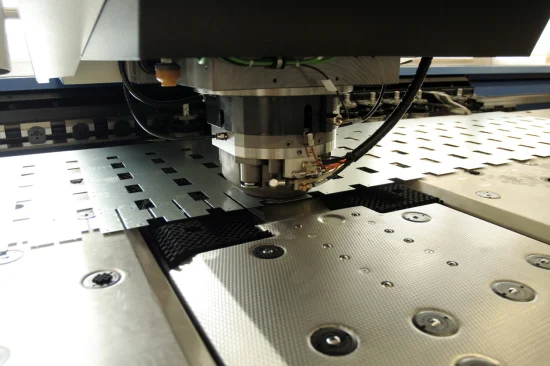

| Equipments | High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T available. |

Huzhou Dear Industry. found in 2008, we operate an plastic injection factory and a die-casting factpry, capable of injection molding production and zinc alloy/aluminum alloy die-casting production, as well as the corresponding mold design and manufacturing. Our premium service team communicates with customers to grasp their needs in a timely and efficient manner and accurately conveys them to our technical section; our superior engineer team uses their professional knowledge to provide customers with the best solutions tailored to their needs in terms of cost, product quality, and production stability, etc. At the same time, we have excellent resource integration capabilities to provide customers with one-stop service. The 4 assembly lines in the assembly workshop assemble parts into final products and package them for shipment, saving customers the trouble of contacting multiple suppliers.Please feel free to contact us if you have any purchase or design needs for individual parts or complete products. We will always be there for you 7x24.

CNC WorkShopIn mold manufacturing, CNC machining is often used to create the core and cavity of the mold, which are the parts that form the

shape of the molded part. The process can also be used to create other mold components, such as inserts and ejector pins. EDM/WEDM

* The accuracy of wire cutting is comparable to that of a grinder (0.005 mm unit) * In addition to straight cutting, it can also

cut into arcs and process complex shapes, such as a combination of straight and arcs. * As long as it is a conductive material, it

can be machined from sheet to cemented carbide regardless of the thickness, size and hardness of the material. CMM

There are many features measured by the CMM, and almost all types of dimensional measurements can be measured by the CMM. Through

the structural features, it is possible to detect flatness, roundness, concentricity, etc. How To Order

1. Experience

Since the company was established in 2008, we have more than 14 years of experience in the field of die-casting(mold)manufacturing and die-casting parts.

2.Design Ability

We have an excellent Design Team, 11 senior engineers work on different projects.We listen voice from our clients and give them good advice to make sure the production more economic and efficient, also makes the product more functional.

3.Good Communication

Communication is one of the most important factors in our cooperation. Our sales and engineers can best grasp the demands of customers, understand their intentions, and provide the best products to them

4.One Stop Service

We have not only die-casting production, but also design and assembly capabilities. We can source parts according to customer demands and assemble finished products for shipment

5.Quality Control

Our quality control includes IQC(incoming quality control), PQC(production quality control) and FQC(final quality control). With QC report for every batch of production, all production data is recoreded in our ERP system.

6.Fast delivery

We do plan and time table for projects, so it's no need to worry about delivery, also We have ability to handle urgent orders.

Q1. ARE YOU A FACTORY OR TRADE COMPANY?

--Yes, we are a factory, is a one-stop source forall of your customized products. Q2. CAN YOU HELP ME TO DESIGN MY PRODUCT OR IMPROVE MY DESIGN?--Yes, we have a professional design team to help our customer to create their product or improve their design. We need sufficient communication before design to understand your intention.Q3. HOW TO GET A QUOTATION?--Please send us drawings in IGS,DWG, STEP file, etc. Detailed PDF together wil e great. If you have any requirements, please remark. Wecould provide professional advice for your refer-ence. The sample will be okay if no drawings, theen we will build and send you a clear and concise drawing to confirm before the quote. Meanwhile, we will keep our promise about the confidentiality of the drawing.Q4. CAN YOU DO ASSEMBLY AND CUSTOMIZED PACKAGE?--Yes, we have assmebly line, so you can finish the production line of your product as the last step in our factory.Q5. DO YOU PROVIDE FREE SAMPLE?--Yes we offer free sample but do not afford the shipping cost.

Q6. WHO OWNS THE MOLD IF I PAY FOR MOLD FEE?

--You paid the mould so it all belong to you forever, and we will give lifelong maintenance. If necessary, you can take this mould back.

Q7. HOW CAN YOU KEEP YOUR PROMISE ABOUT QUALITY?

--We have an independent quality department to check every step by IQC, IPQC, OQC.If there are any defective items we willl take corrective action to ensure the elimination of the root cause of defects. When you get the goods and find there is a defect after check. We promise to accept your asked return at our cost or provide replacement free.

Q8. WHEN WILL YOU SHIP THE DIE CASTING UNITS OR THE T1SAMPLE?

--Normall,it takes 20-60 business days for the mold, then we will send you T1 sample for approval. And 15-30 business days for mass production.

Q9. HOW TO SHIP?

--The free sample or small order is usually sent by TNT,FEDEX,UPS,etc,and the big order is sent by air or sea after clients confirm.

YOU MAY ALSO NEED PLASTIC INJECTION SERVICE