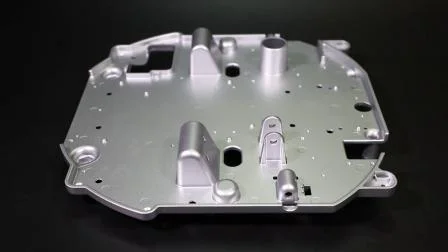

Hot Selling Zinc Alloy Die Castings A380 Aluminum Die Castings

Basic Info

| Model NO. | ZCC-070 |

| Pressure Chamber Structure | Horizontal |

| Tolerance Grade | 4 |

| Casting Surface Quality Level | 2 |

| Certification | ISO 9001:2015 |

| Trade Mark | No |

| Tolerance | +,-0.015mm |

| Mold Life | 300000 Life |

| Transport Package | Wood Box |

| Trademark | Double HH |

| Origin | Ningbo |

| Production Capacity | 100000 |

Product Description

Customized Small Parts Aluminum Die CastingDie casting is an efficient and economical manufacturing process. It is used to produce geometrically complexmetal parts that are formed by reusable molds, called dies. These dies generally offer a long service life, andthey are capable of producing visually appealing components.The die casting process involves the use of a furnace, molten metal, a die casting machine and a die that hasbeen custom-fabricated for the part to be cast. The metal is melted in the furnace and then the die casting machineinjects that metal into the dies.

There are two main types of die casting machines:

- Hot-chamber machines (used for alloys with low melting temperatures, such as zinc)

- Cold-chamber machines (used for alloys with high melting temperatures, such as aluminum)

In both machine types, after the molten metal has been injected into the dies, the metal cools rapidly and solidifiesinto what becomes the final part, called the casting. Typically, that casting will be subjected to one or more finishingprocesses prior to final assembly.

Material & Temper | Zamak 3, Zamak 4 or customized . |

Film Standard | Powder coating: 60-120 μ , Electrodeposited film: 12-25 μ. |

Part Weight | from 3 g --- 2kg |

Thickness | 2mm-20mm or Customized. |

Surface Treatment | Electroplate, Powder Coating,Polishing, Brushing, etc. |

Application | Industry fittings and Construction and Decoration. |

Casting Machine | 88-500tons |

Capability | Output 100 tons per month. |

Deep Processing | CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

MOQ | As custimer's . Usually 5-10 tons for a 20'FT; 20-23 tons for a 40HQ. |

OEM | Available |

Ningbo Junjiaxuan Metal Technology was set up in 2021 and the factory was founded in 1978, which covers an area

of 7,000 square meters. Located at Yuyao, Ningbo city that north to Shanghai for 180 Kilometers, east to Ningbo Beilun port for

60 Kilometers.

We are the professional and experienced manufacturer in producing Aluminum die castings, Zinc die castings,CNC machining and

Metal conveyor belt.With the main facility of 125T,160T, 250T, 400T Cold Chamber die casting machines and one hot chamber die

casting machine with capacity of 88T, also including 2sets of CNC machines and several assembly lines.

Junjiaxuan provides all-round production services from design and development of mould to the forming and post-processing of die

casting products as well as surface treatment. The products are mainly used for 3C industry, furniture parts, medical equipment,

electrical appliances and so on.

Junjiaxuan is committed to competitive price and reliable quality, we also taking great efforts to quick and prompt service, keeping

close ties with clients and always having an open and clear channel of communication with all business parters.

· 24 Hours Support On line· 100% Inspection before Packing

1. Are you a manufacturer or a trading company?

We are a professional manufacturer with over 19 years′ export experience for designing and producing multi die casting parts. especially in high pressure die casting.

2. How can I get some samples?

If you need, we are glad to offer you free samples, but customer are expected to pay tooling charge for new design product, and the cost will be deducted for mass production.

3. Can you make casting according to our drawing?

Yes, we can make casting according to your drawing, 2D drawing, or 3D CAD model. It would be better if 3D CAD model can be shared,so that we can design moulds more efficient.

4. Can you make casting based on our samples?

Yes, we can make measurement based on your samples to make drawings for tooling making.