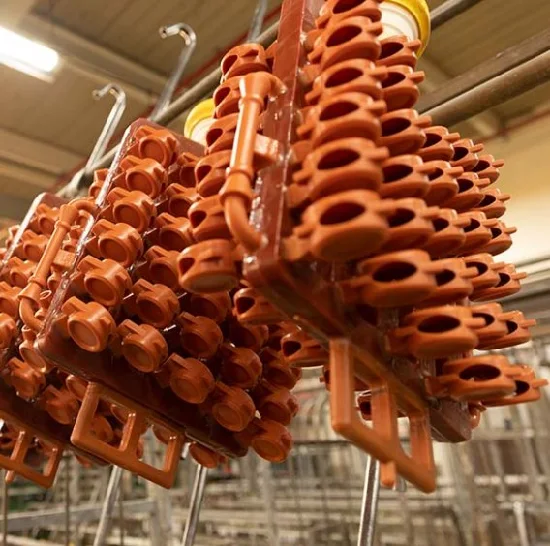

OEM Custom Made Fabrication Precision Brass Stainless Steel Aluminum Titanium CNC Milling Turning Parts CNC Machining Service

Overview Company Profile Shenzhen Jiahao Xinda Technology Co., Ltd. established in 2009, is a pure-play enterprise dedic

Basic Info

| Model NO. | JHX |

| Material | Aluminum,Brass,Iron, Stainless Steel,Plastic,Nylon |

| Application | Metal Recycling Machine, Metal Cutting Machine, Metal Processing Machinery Parts, Metal forging Machinery, Metal Drawing Machinery, Metal Coating Machinery |

| Accuracy | +-0.01mm |

| Shipment | Express, by Air,by Ship,or as Your Requesst |

| Surface Finish | Sandblasted/ Anodized/ Plated/ Customized |

| Business Type | Factory |

| Qualiy Control | Professional QC 100% Inspection Before Shipping |

| Customer Logo | Support |

| Sample Leadtime | 5-7 Days |

| Mass Production | to Be Negotiate |

| Transport Package | Internal Foam and Outer Carton |

| Specification | customized |

| Trademark | OEM |

| Origin | Shenzhen, China |

| HS Code | 76169910 |

| Production Capacity | 1000000/Year |

Product Description

Company Profile

Shenzhen Jiahao Xinda Technology established in 2009, is a pure-play enterprise dedicated to developing and manufacturing nonstandard machine parts and equipment processing, covering an area of 5600 square meters. Our plant is located in Fuyong Town, Bao'an District, Shenzhen City. Owning advanced technologies and strong technical force, we have nearly 100 staff, including 30 engineers in management. We have over 40 professional manufacturing and possessing equipment, which includes CNC, milling machine, lathe machine, precision grinding machine and line cutting machine.

There are various testing equipment imported with high precision in our quality department, including 3D and 2.5D measuring equipment, altimeter and hardness tester.

Company Activities

Packaging & Shipping

For sample orders, TNT,UPS,SF express ,FedEx ,DHL, are optional. For mass production, by air, by truck ,by railway ,by sea are optional.

1.Are you a manufacturer or a trading company?We are a 12600-square-meter factory located in Shenzhen, China.

2.How can I get a quote?Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information.

3. Can I get a quote without drawings?Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.4.Will my drawings be divulged if you benefit?No, we pay much attention to protect our customers' privacy of drawings, signing NDA is also accepted if need.5. Can you provide samples before mass production?Sure, sample fee is needed, will be returned when mass production if possible. 6. How about the lead time?Generally, 1-2 weeks for samples, 3-4 weeks for mass production.7. How do you control the quality?(1) Material inspection--Check the material surface and roughly dimension.(2) Production first inspection--To ensure the critical dimension in mass production.(3) Sampling inspection--Check the quality before sending to the warehouse.(4) Pre-shipment inspection--100% inspected by QC before shipment.8. What will you do if we receive poor quality parts?Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap.

Send to us