Plastic Injection Mold Design and Molding Service with SGS Certification

Basic Info

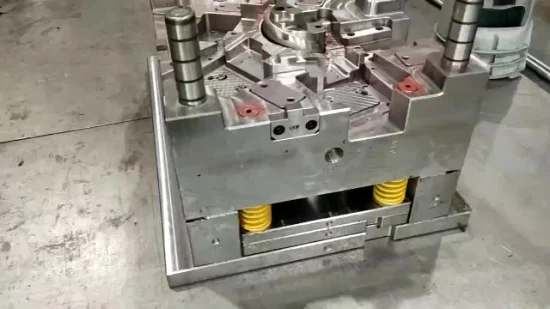

| Model NO. | HW-130 |

| Mould Cavity | Multi Cavity |

| Plastic Material | ABS |

| Process Combination Type | Single-Process Mode |

| Application | Car |

| Runner | Cold Runner |

| Design Software | Pro-E |

| Installation | Semi Fixed |

| Certification | ISO |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | Any Question Please Feel Free to Contact Us. |

| Mould Life | >300 Thousand Times |

| Material of Steel | S136, S136h, 718h, Ramax 168 |

| Gate Type | Side Gate, Sub Gate, Pin Point Gate, Edge Gate etc |

| Lead Time | 15-45 Working Days |

| Injection Machine Tonnage | 50t-3600t |

| OEM/ODM | Welcomed |

| Transport Package | Wooden Box Packing |

| Specification | Custom |

| Trademark | HOWE or Custom |

| Origin | China |

| HS Code | 8522901000 |

| Production Capacity | 40sets/Month |

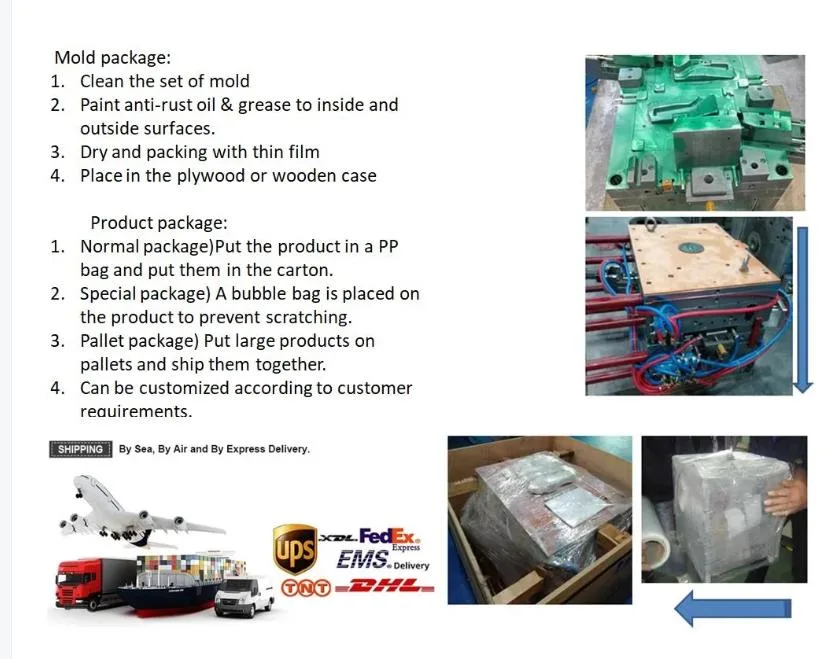

Packaging & Delivery

Package size per unit product 40.00cm * 30.00cm * 20.00cm Gross weight per unit product 20.000kgProduct Description

Product Description

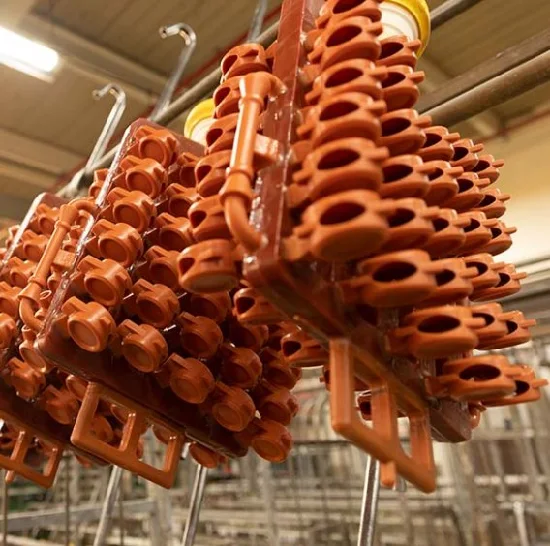

| Name | Injection Mold Design And Plastic Molding Service |

| Product Material | ABS,AS,PP,PC,PE,POM,PMMA,PS,HDPE,TPE,TPU etc |

| Surface finish | Polishing finish,Texture Finish,Glossy Finish,Painting,Slik print,Rubber Painting etc |

| MOQ | 1000PCS |

| Packaging details | Carton box or wooden Case upon product weight and customer's requirements. |

| Shipping | By sea or by air as customer requirement |

| Export Country | Janpan,Europe,USA,Mexico,Australia,Middle East,Korea,Asia etc |

| Typical Used For | Housings, containers, caps, fittings,including as below |

| Power-tool housing, Disposable razors, Electrical Switches,Crates/Recycling boxes | |

| Automotive dash boards,Television Cabinets,Drug Inhalation Units,Automotive bumpers, | |

| Wheelie bins ,Syringes,Telephone handsets ,Washing-up bowls,DVDs, | |

| Bottle Lids/closures,Battery Casings | |

| Range of markets | industrial, consumer, food processing, aviation, seals/gaskets, lighting, packaging, filter, healthcare, |

| telecommunications, mechanical, water treatment, appliance, recreation, lawn and garden, | |

| educational, oil and gas, government, construction, plumbing, surveillance, pumps, marine, motors, | |

| gears, RFID tags, electronics, and fasteners. |

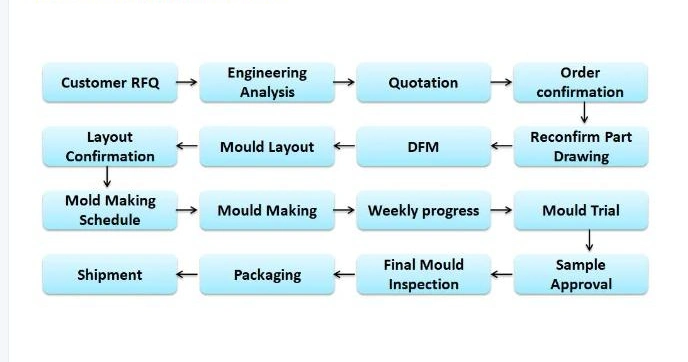

Project Management Process

1. According to 3D drawing or samples for quotation.2. Including the price of moulds, moulds sizes, material for cores & cavities, weight of product, part cost, payment, moulds lifetime, delivery, etc.3. After the customer confirming the mould design and quotation.4. Confirm drawing, start to do DFM,mold flows and mold detail agreed with the customer, start production.5. Every week we will feedback to the customer a mold progress(picture).6. We provide the moulds test samples for confirmation(about 10-15 piece), then, get your signature sample ,mass production.7. Wooden case for moulds, cartons for parts ,or as your requiretment.8. deliver goods by air or by sea.

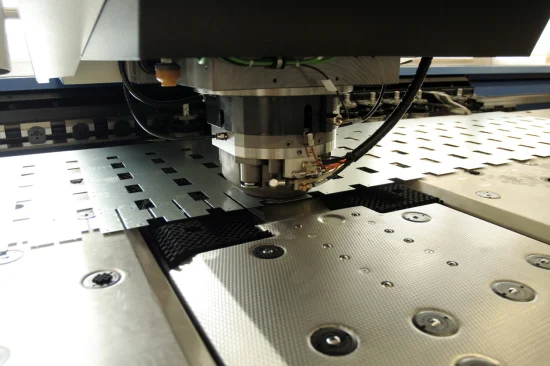

How to get a suitable and quality mold?The engineer consultant will work with you to analyze the mold structure and get your product development cost gudget ASAP.Mold flow analysis before mold design, process, packaging methods, shipping cost and time.

Howe built in 2010. Ourcompany specializing in the design and manufacture of high-quality die casting molds and die casting parts for the international market and have been engagaed in the manufacturing sector since our inception. Howe is an OEM/ODM factory, customized your products to meet your needs is our advantage. We are managed by a group of professionals with many years of experience in mold design, molding technology and Quality control. We have developed and excellent designers will ensure that your imagination is incorporated into the actual product. If you want to create prototype or mass-produce in a very specific project, we can help you achieve your vision!

Customer visiting