Precision Custom Hardware Casting Part Accessories Magnesium Zinc Aluminum Metal Parts Die Casting Tool

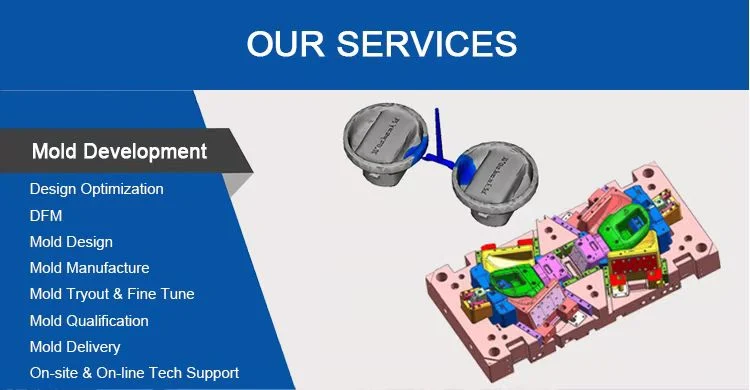

Mold and precision molding processing are our core business. When you choose Jingsheng, you will get a professional part

Basic Info

| Model NO. | YZ0011 |

| Pressure Chamber Structure | Vertical/Horizontal |

| Tolerance Grade | 7 |

| Casting Surface Quality Level | 2 |

| Certification | CE, RoHS, ISO 9001:2000, ISO 9001:2008 |

| Mold Life Time | 200K Times |

| Mold Material | SKD61 H13 8407 |

| Mould Cavity | Single Cavity, Multi-Cavity. |

| Size | According to Customers′ Drawings or Samples |

| Drawing Format | Step, Dwg, Igs, Pdf |

| Payment Term | T/T, L/C, Trade Assurance |

| Product Material 1 | ADC10, ADC12, A360, A380, A413, A356, Lm20, |

| Product Material 2 | Zinc Alloy 3#, 5#, 8# |

| Surface Treatment 2 | Sand Blast, Shot Blast, Anodine Polish |

| Surface Treatment 3 | Zinc Plating/Chrome Plating/Pearl Chrome Plating/ |

| Surface Treatment 4 | Nickel Plating/Copper Plating |

| Transport Package | Wooden Case/Cartons/Pallet/Customized |

| Specification | Customized |

| Origin | China |

| Production Capacity | 100000pieces/Month |

Product Description

Mold and precision molding processing are our core business. When you choose Jingsheng, you will get a professional partner in the whole production process to bring your products from concept to reality.

Q1: Can I get free samples and how long will it take?

A1: For the standard products we have in stock, we can provide samples free of charge, and the express cost is borne

by the customer.

For customized products, the sample cost is determined according to the product requirements. It usually takes about 7 days

to send it.

Q2: Can you customize parts according to my samples or drawings?

A2:Yes,you can send us drawings online or by email , or send us samples. We will scan the features according to the drawings

or samples and draw 3D drawings for production.

Q3: What is the delivery time?

A3: 25-35 days after confirming the product drawing and receiving the advance payment, the specific delivery time depends

on the goods and quantity you ordered

Q4: What does your OEM service include?

A4: We follow your requirements from design concept to mass production. You can provide us with 3D drawings, and then

our engineers and production team evaluate the design and make suggestions on product modeling/ production

B. If you don't have 3D drawings, you can provide 2D drawings or sketches with full-scale feature details. We can draft 3D

drawings for you at a reasonable charge.

C. You can also customize the logo on the product surface packaging and cartons.

D. We also provide assembly services for OEM parts

Q5: What is your payment term?

A5: we accept paypal, credit card, Westen Union remittance and other online payments. For regular orders, the payment tems

are 30% deposit and full payment before shipment.

Q6: Are you a manufactureror factory or a trading company?

A6: We are a manufacturing factory.Welcome to visit our factory anytime.

Send to us