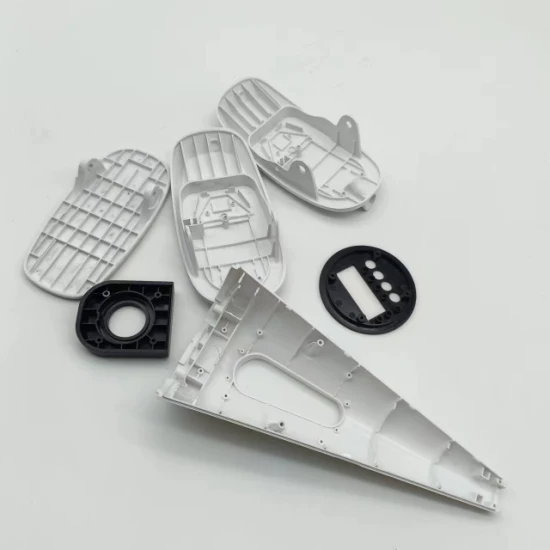

Lk Yizumi Buhler Aluminum Aluminium Die Casting High Pressure Cold Chamber Aluminium High Pressure Gravity Die Casting

Basic Info

| Model NO. | Aluminum Die Casting |

| Die Casting Machine Type | Cold Chamber Die Casting Machine |

| Die Casting Method | Precision Die Casting |

| Application | Auto Parts |

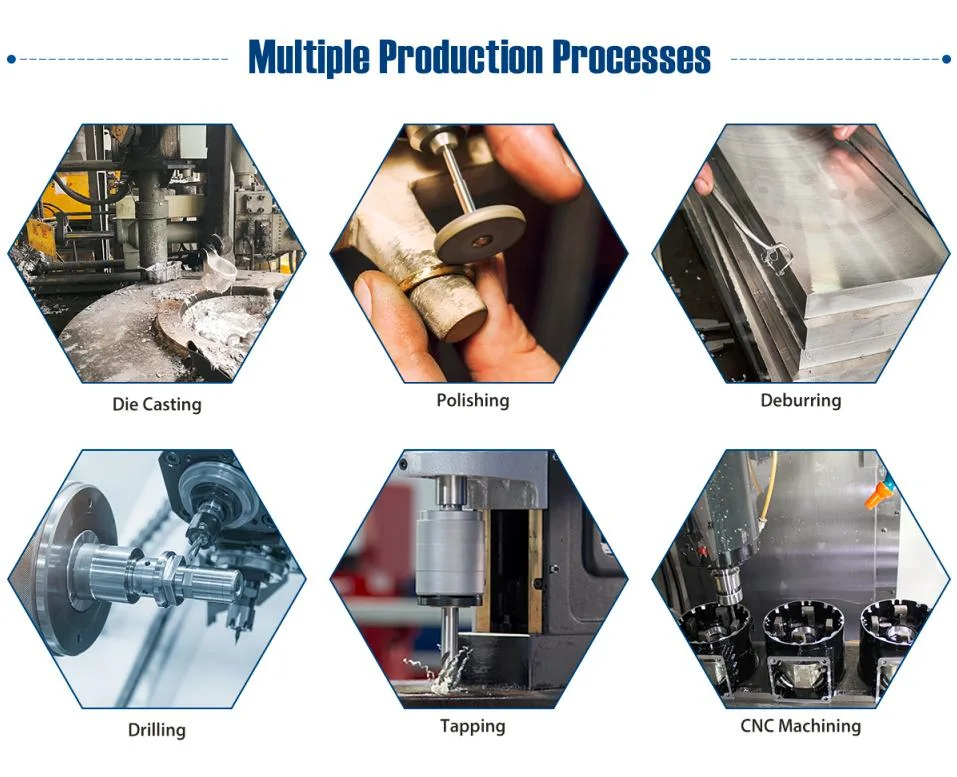

| Machining | CNC Machining |

| Material | Aluminum Alloy |

| Surface Preparation | Deburring |

| Pressure Chamber Structure | Horizontal |

| Tolerance Grade | 8 |

| Casting Surface Quality Level | 1 |

| Certification | CE, RoHS, ISO 9001:2000, ISO 9001:2008 |

| Transport Package | Plastic Net, Carton Box, Pallet |

| Specification | 100*80*80cm |

| Trademark | Can be customized |

| Origin | China |

| HS Code | 8480410090 |

| Production Capacity | 3000000/Year |

Product Description

1, Aluminium die casting is a process of injection aluminum alloy under pressure, which produces parts in high volume at low costs.

2, There are two processes of Aluminum die casting: hot chamber and cold chamber.

3, A complete cycle can vary from one second for small components to minutes for a casting of large part, making aluminium die casting the fastest technique available for producing precise aluminium alloy parts.

4, Shanghai Yeevalves Company Limited ---we have a strong and highly efficient R&D team, which will design and make OEM/ODM products according to your drawings and samples.

5, Certification: TS16949, ISO9001, SGS, ROHS

Technical Support

Shanghai Yeevalves is a professional at independent development and design. Our engineers are skilled at AUTO CAD, PROENGINEER,

SOLID, SketchUp. 3D max WORKS and other 2D & 3D software. We are able to design, develop, produce and deliver your PO according

to your drawings, samples, or just an idea. control of non-standard products and OEM products.

Quality Control

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details beforethe production line operated

3) Have a full inspection and routing inspection during mass production---In-process quality

control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC) 5) Checking the goods after

they are finished-----Outgoing quality control(OQC)

Company Profile

Yeevalves Company was founded in 2011, and based onFoxmold's original business, it has expanded the professionalhydraulic companies of hydraulic pumps, hydraulic valves, hydraulic stations, hydraulic synchronous lifting and hydraulicsystem solutions.

Our company covers over 30,000 sqm with abundant technology force, good condition of production and examination,and perfect after-sales service. Our company has passed through authentication of ISO9001:2008 quality systems We keep an eye on technical innovation, quality and service, with spirit of "credit innovation, doer, efficiency" andmanagement principle of "mutual benefit" pursuing the mutual development with our customers, reducing cost constantly tolet customers like to purchase our products.

1. Every order wil be well-packed and sealed before shipment, we promise you that the goods will reach your hand in safe and as fast as possible.2. Different products we will use different packing:3. Usual packing:by pearl cotton/bubble bag + carton box4. Special packing(for large part/large quantity order):by pearl cotton/bubble bag + wooden box

After Sales Servicea) Good after-sale service, all questions will be replied within 12 hours.

b) Customized design is available. ODM&OEM are welcomed.

c) We can provide free sample, consumer should pay the freight first.

d) Convenient transportation and fast delivery, all available shipping ways could be applied, by express, air or sea.

e) High quality and most competitive price.

f) Advanced produce and inspecting equipments.