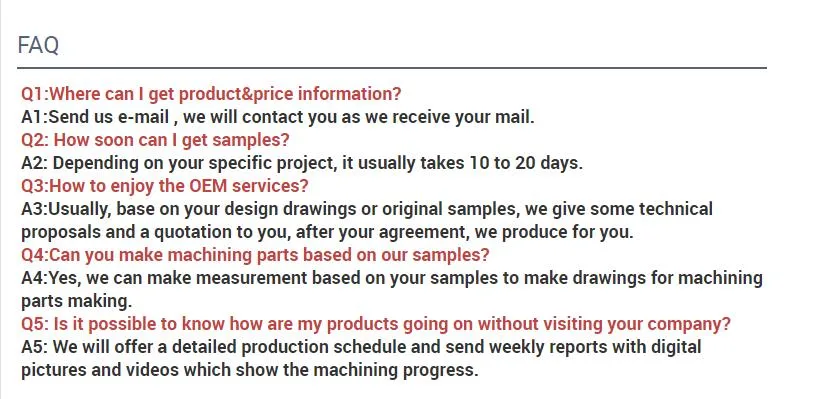

Aluminum Casting Parts/Window Casting Components/Angle Corner/Zinc Alloy Casting/Aluminum Die Casting

Our company specializes in the production of all kinds of non-standard metal parts. The processing technology of our com

Basic Info

| Model NO. | Various models |

| Pressure Chamber Structure | Process Selection Based on Product |

| Tolerance Grade | Control Tolerance According to Customer Requiremen |

| Casting Surface Quality Level | According to Customer Needs |

| Certification | CE, RoHS, ISO 9001:2000, ISO 9001:2008 |

| Experience in Machining | 20 Years |

| Quality | High Quality Products |

| Production Schedule | Keep Track of Workshop Production Progress |

| Production Time. | Support The Urgent |

| Transport Package | According to Customer Needs |

| Specification | Various specifications |

| Trademark | Lingzhong |

| Origin | Wenzhou City, Zhejiang Province, China |

| Production Capacity | 10000000PCS/Year |

Product Description

| Service | CNC Machining/Turning and Milling/CNC Turning/OEM Parts/Cold heading / casting / forging / stamping | |

Metal | Aluminum | Aluminum 2024 Aluminum 5052 Aluminum 6061-T6 Aluminum 6063-T6 Aluminum 7075 ADC12 |

| Stainlesss steel | SUS303,SUS304,SS316,SS316L | |

| steel | 12L14 4140 1018 1045 12L14 4130 4142 ,O1 tool steel | |

| D2 tool steel,A36 1008 ,Alloy42 | ||

| Titanium | Grades 1-4 Grade 5 Grade 9 | |

| Brass | 260, C360,H59,H60,H62,H63,H65,H68,H70 | |

| Finish Result | |

| As Machined | Sharp edge and burrs will be removed |

| Bead Blast | The part surface is left with a smooth, matte appearance |

Anodized | Type II creates a corrosion-resistant finish. Parts can be anodized in different colors-clear, black, red, and gold are mostcommon-and is usually associated with aluminum. |

| Type III is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II. | |

| electroplating chromium | electrophoresis, QPQ(Quench-Polish-Quench) |

| Electro Polishing | Chrome Plating, Knurl, Laser etch Logo, etc. |

| Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. |

| Tolerance | +/-0.005mm |

Our company specializes in the production of all kinds of non-standard metal parts.

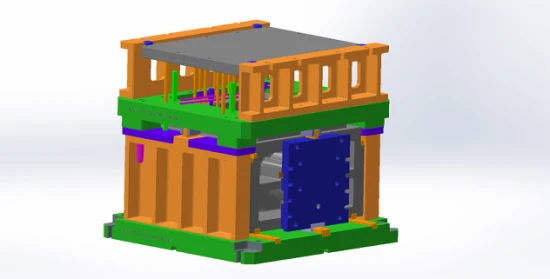

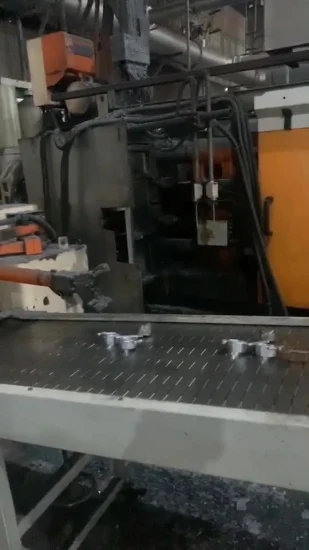

The processing technology of our company includes CNC machining, precision casting, precision forging, cold heading processing, stamping, laser cutting, wire cutting, electric pulse, argon arc welding, laser welding, precision grinding machine, hardness tempering, surface plating, product oxidation and so on.

Our company can process all kinds of aluminum alloy, copper alloy, zinc alloy, stainless steel, carbon steel, iron, magnesium alloy and other materials.

Our products include AUTO PARTS, auto air conditioning parts, EVAPORATORS, condensers, PIPE ASSEMBLIES, PIPE FLanges, JOINTS, nuts, expansion VALVES, elbow pipes, pressure switches, silencers, aluminum sleeves, sleeves and other auto parts.

Our company can manufacture all kinds of non-standard metal parts according to customer requirements, including shaft, shaft sleeve, piston rod, connector, all kinds of casting parts, forging parts, stamping parts, flange joints, pneumatic parts, hydraulic parts, hardware parts, fasteners and so on.

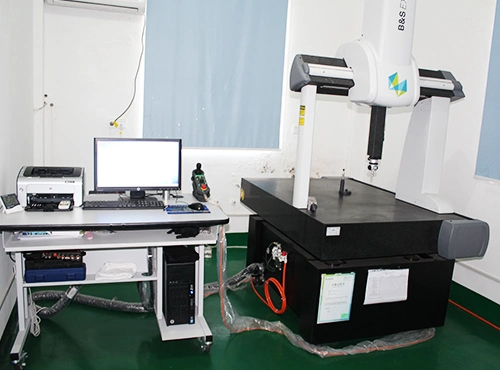

Our company has 20 years of manufacturing experience, products sold all over the world, product quality has been recognized by customers. Our company has excellent technical team, advanced processing equipment, efficient service team. Looking forward to long-term friendly cooperation with you.

Send to us