Professional Permanent Die Cast Mould Housing Auto Parts Aluminum Die Cast Mold Aluminium Alloy Mold Tooling Mould Precision Casting Mold Factory

Professional Permanent Die Cast Mould Housing Auto Parts Aluminum Die Cast Mold Aluminium Alloy Mold Tooling Mould Preci

Basic Info

| Model NO. | BQ-M |

| After-sales Service | Online or on-Site Installation |

| Warranty | 1 Year |

| Application | Car, Motorcycle |

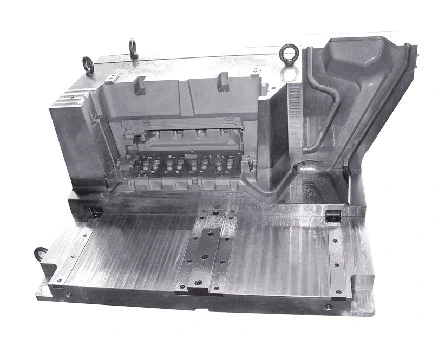

| Material | Steel |

| Demoulding | Pull Core |

| Surface Treatment | Heat Treatment |

| Using Hardness | >HRC45 |

| Average Wall Thickness | >3mm |

| Mould Life | <500,000 shots |

| Certification | CE |

| Customized | Customized |

| Condition | New |

| Cavity | Customization |

| Mold Material | H13, 38cr, SKD62, Cast Iron and Others |

| Transport Package | Nake |

| Specification | Customization |

| Trademark | BOQIAO |

| Origin | China |

| HS Code | 8480490 |

| Production Capacity | 1000 Sets/ Year |

Product Description

Professional Permanent Die Cast Mould Housing Auto Parts Aluminum Die Cast Mold Aluminium Alloy Mold Tooling Mould Precision Casting Mold Factory

Product Description

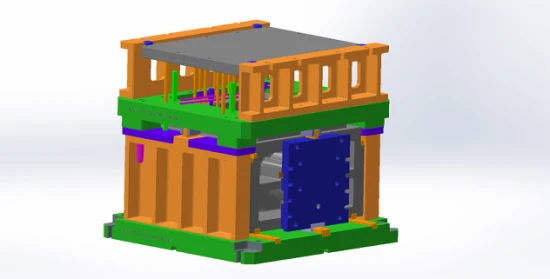

| Product name | Permanent mold for aluminum alloy |

| Mold material | Cast Iron, 38Cr, SKD11, H13 ..... |

| Aluminum material | ADC12, A356.2, A380, 6061, 6063 ...... |

| Mold life | 10000-60000 shots |

| Die casting process | High pressure and low pressure and gravity casting |

| Mold design | Product drawing, samples or customization |

| Mold test | 3D Laser scanner, surface hardness testing |

| Product test | CMM, X-ray testing |

| Delivery time | 30-60 days after confirming plan |

| Package | Naked package with anti-rust treatment |

Products Show

We can provide customers with a complete set of low-pressure casting products.The initial period,for example, the upfront budget for products not in production, including the budget for production costs, the budget for molds and equipment, and the development of production processes in the medium term, in addition to providing qualified equipment to customers. The process of producing the product is developed, and the entire production process is handed over to the customer,training and ensuring that the customer can understand and learn, then fully grasp th e production process of low pressure casting. In the later stage, in addition to providing warranty service during the warranty period, a lifetime paid maintenance service will be provided after the warranty period. In addition, we can also provide equipments and processes for heat treatment of aluminum alloy products, such as aluminum alloy aging furnace(T4), aluminum alloy vertical quenching furnace(T6),etc. and provide a variety of casting equipments including resistance melting furnace.

Our Factory

Nanjing BoQiao Machinery is a professional designer and manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Our products including gravity casting machines,low-pressure casting machines,melting furnaces, annealing furnaces,quenching furnaces,aging furnaces, transverse magnetic furnaces and other kand of furnaces. We have 18 types and nearly 100 specifications of products. We can provide customers with all kinds of universal solutions and we can do turnkey projects including technical consultation, equipment selection, mold manufacturing, process development, operation training and so on.Our machines really help a lot for our customers. Products are widely used in : electric power fittings, motorcycle parts,auto parts,new energy industry,electronics, electricals, high-voltage switches, engineering machinery, aerospace castings, fans, household appliances and other professional casting production lines. Since the year of 1999, our company has manfactured and sold more than 2000 units of machines. Reliable quality and excellent service help our company gain a good reputation from our customers. In addition to domestic sales, our products have obtained a good market share in Southeast Asia, Africa, South America, Middle East and other parts of the world. Based on the business philosophy of cooperation, win-win, honesty and sincerity, BoQiao will continuously improve products quality and services to better meet our customers' needs and help them do their business better and better.

Quality Control

Company owned tensile testing, hardness testing, three-coordinate instrument, spectrum analyzer, X-ray testing, etc testing equipment. We can meet different clients' high required quality testing.

Customer Visiting

Our products have exported to Europe, North America, South America, Southeast Asia, Asia and others more than one hundred countries and regions, service and price are our advantages, customer trust is our motivation of development.

Send to us