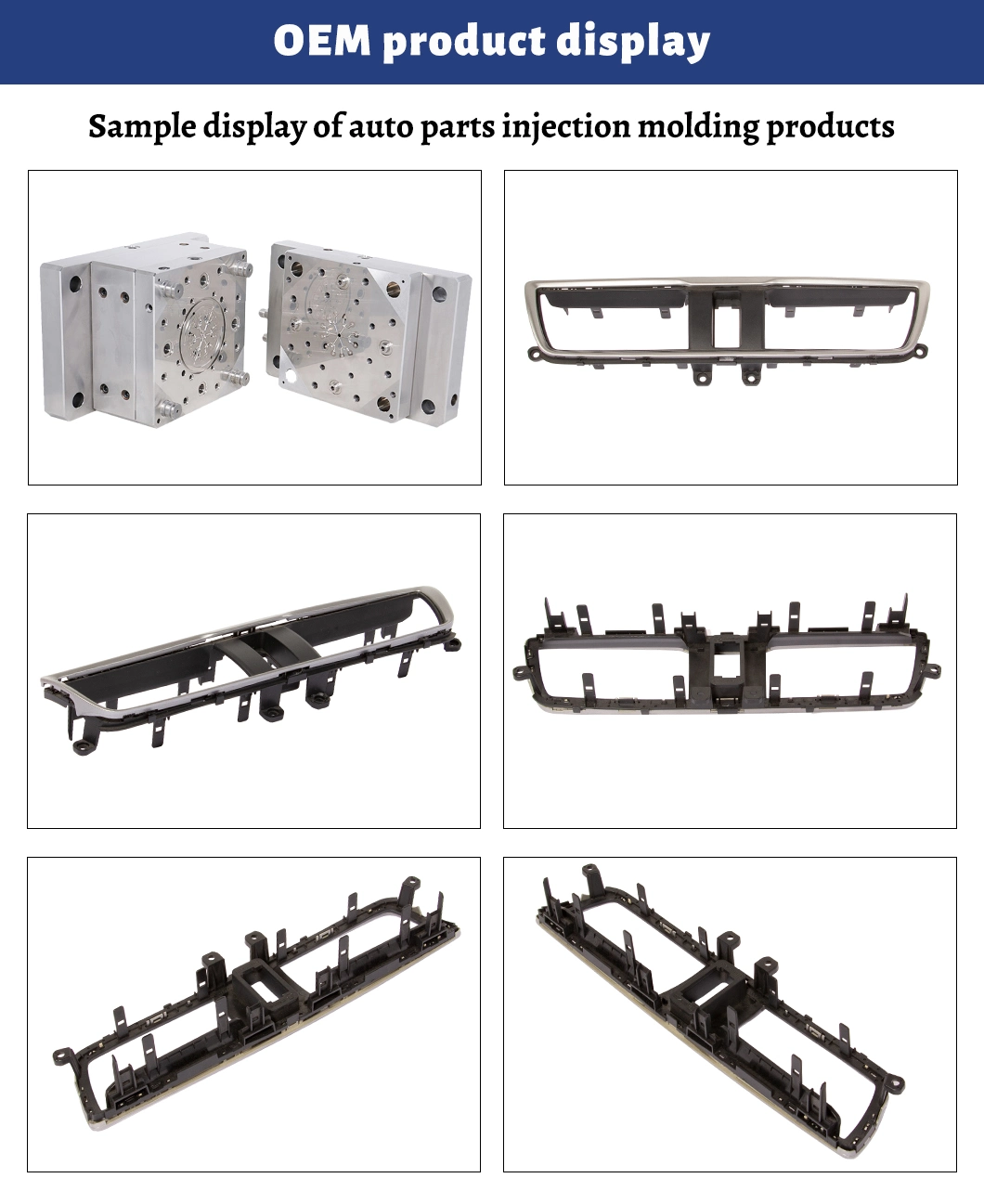

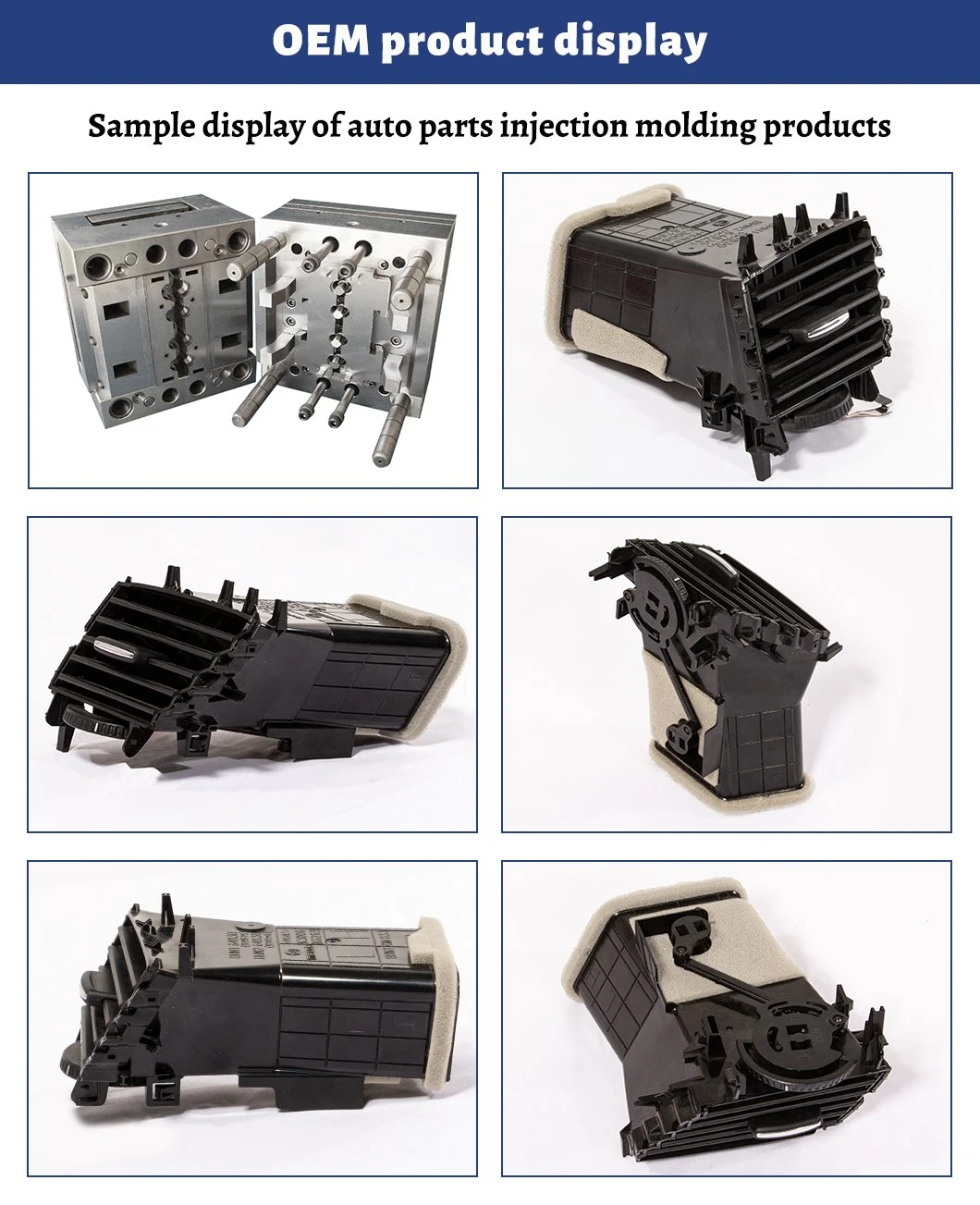

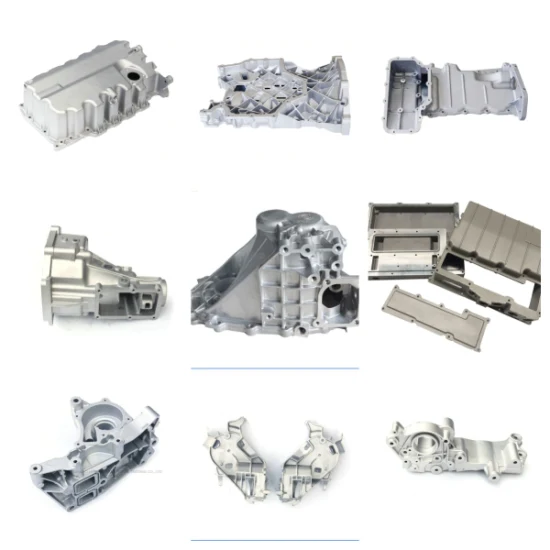

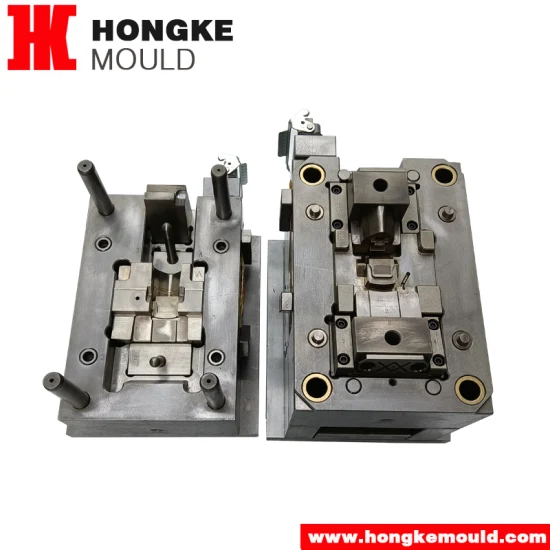

Custom High Quality Mould Maker Product Polycarbonate ABS Acrylic Plastic Injection Molding Parts Service

Basic Info

| Application | Electronic |

| Runner | Hot Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | TS16949, ISO, UL, E338951 |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | 24 Hours Reponse, Online Tech Support |

| Transport Package | Standard Export Package |

| Origin | Made in China |

| Production Capacity | 600 Die Sets / Year |

Product Description

Portable power station, car door trim panel, full face simplus mask, printer, monitor stand, famous plastic enclosure OEM manufactuer

What is injection molding?

Injection molding is a method of producing parts by injecting material into a mold. Metals (for which the process is known as die-casting), glasses, elastomers, confections, and, most commonly, thermoplastic and thermosetting polymers can all be used in injection molding. The part's material is fed into a heated barrel, mixed, and forced into a mold cavity, where it cools and hardens to the cavity's configuration. After a product is designed, usually by an industrial designer or engineer, molds are made from metal, usually steel or aluminum, and precision-machined to form the desired part's features. 3D printing materials like photopolymers which do not melt during the injection molding of some lower temperature thermoplastics can be used for some simple injection molds. Injection molding is widely used for producing a wide range of parts, from very small to very large. The ability to produce parts with varying geometrical shapes and sizes is determined by the type of machine used in the operation

| Product name | Customized mould mold making plastic injection plastic enclosure portable power station |

| Material | ABS, PP, Nylon, PC, POM, PU, TPU, TPV, PBT, PC+ABS, PE, PA6 |

| Weight | 2g-2kg |

| Drawing | Provide by customer(DXF/DWG/PRT/SAT/IGES/STEP etc),Or design according as the sample |

| Equipment | Injection molding machine |

| Surface treatment | Electroplate,paint spraying |

| Application | Auto parts,auto door handle,Car tank cap, housing/cover/case/base, telescope, daily goods, home&office appliances, other industrial spare parts, customized |

| Quality | 100% inspection before shipping |

| Packing | Carton packaging, or PVC bag with a label; Wooden pallet; as customer's requirement |

| Service | OEM service available, High Quality Competitive Price prompt delivery. 24-hour service with prompt reply |