Pet Polycarbonate Corrugated Sheet Extrusion Process

PC Transparent Corrugated sheet picture from our Extrusion Line Our Company Main Plastic Sheet Extrusion Line Show 1. PE

Basic Info

| Screw | Single-Screw |

| Engagement System | Intermeshing |

| Automation | Automatic |

| Computerized | Computerized |

| Main Electrical Parts | ABB, Omron, Rkc, Schneider, FUJI, Delix etc. |

| Customized | Customized |

| Application | Housing Waterproof, Architecture Engineering |

| Model No | Lsj-120/35 |

| Sheet Width | 1220-2150mm |

| Sheet Thickness | 1.5-10mm |

| Die Head | T-Type, Jc-Times Brand |

| Extruder Model | High Efficiency Single Screw Extruder 150/33 |

| Three Roller Calendars | Vertical Type, Alloy Steel Material |

| Transport Package | Wooden Pallets and Cases and Films |

| Specification | 300-400kg/H |

| Trademark | Leader Machinery |

| Origin | Qingdao of China |

Product Description

PC Transparent Corrugated sheet picture from our Extrusion Line

| This Line Consists Of: |

| 1) exhaust-type single screw extruder |

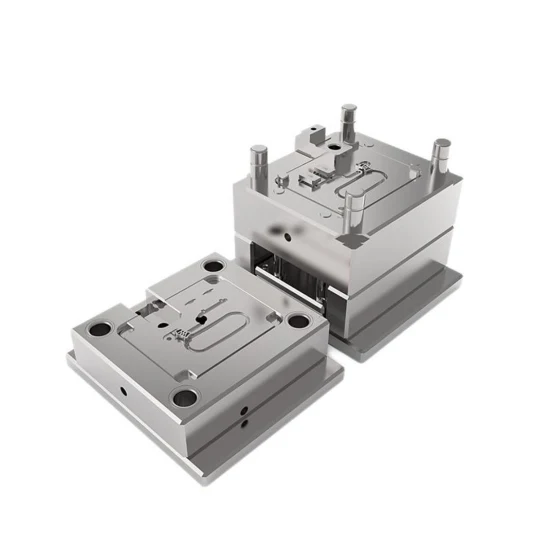

| 2) Mould /T-die |

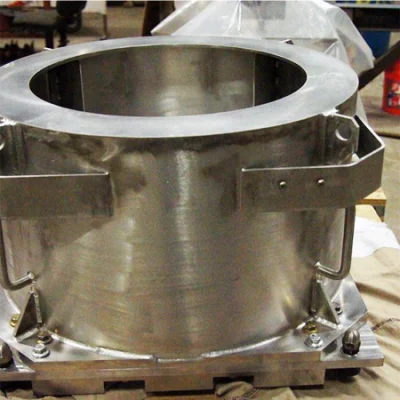

| 3) Three calender roller |

| 4) Roller temperature controller |

| 5) Cooling bracket |

| 6) Forming machine |

| 7) Haul off machine |

| 8) cutter |

| 9)Stacker |

| 10) Feeding material system |

| 11) Electric appliance |

Our Services

1. Warranty for machinery: 18months for mechanical parts, 12 months for electrical parts.-Long Time warranty2. Technical service and support will be forever.-Best service3. We will dispatch four 1-2 engineers from the seller to the buyer's factory for installation and commissioning and training till the buyer's workers can operate the machines independently.- On-site serviceFAQWelcome your inquiry. Please contact with me freely. I am sure you will get quick and Warmly response.1. Please kindly inform me specification of the products you want to produce:If you want plastic pipe, plz Inform us pipe diameter & thickness (SDR)If you want plastic sheet, plz inform us sheet width & thickness.If you want plastic profile, plz send us general size, picture or drawings.2. We will send you the quotation details according to your requirements.Company Information1. Reliable quality with ISO9001:2008 CE GOST SGS certification. We use the famous parts and material. Main electrical parts:ABB,Omron, Schneider,RKC,Siemens. China famous brand Screw, Barrel, T-die, Mould. Such as JC-times mould, JINXING Brand Screw,Made in Zhejiang Zhoushan.2. Global sight and keep up the trend of new technology. We have our own R&D team, and we attend famous and professional Exhibition to realize the variety demands of global customers and learn the New development of The plastic extrusion machine. Such as NPE, K show in Germany, Exhibition of Italy,Turkey, Korea, Russia,Poland, Chinaplas etc.3. Excellent service:We have been engaged in exporting since foundation , Warranty for machinery 18months for mechanical parts, 12 months for electrical parts and technical service will be forever.4. Praise from Customer. Our machines are well recogized by customers after years of good performance of work. They purchased our machine one by one.

Send to us