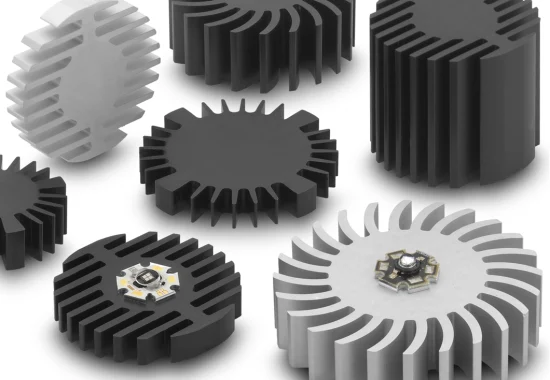

ISO 13485 Cleanroom Manufacturing Dongguan Flexible Mouldings Making Precision OEM Plastic Mould

Overview Package size per unit product 2.00cm * 2.00cm * 2.00cm Gross weight per unit product 0.050kg Company Profile Ho

Basic Info

| Model NO. | HM-IM PM |

| Plastic Material | ABS |

| Process Combination Type | Compound Die |

| Runner | Hot Runner |

| Design Software | AutoCAD |

| Installation | Semi Fixed |

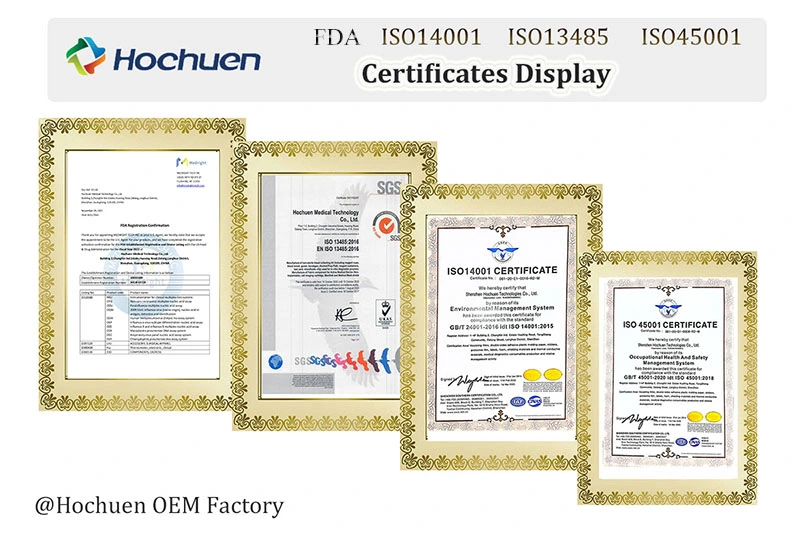

| Certification | ISO, FDA |

| Customized | Customized |

| Material | ABS, PC, PP, or Customized Plastics |

| Injection Molding Type | Injection Molding, Double Color Injection Molding |

| Other Tyoes | Overmolding, LSR Injection Molding |

| Mold Maker | From Design to Manufacturing |

| Product Size | According to Customer′s Design |

| Transport Package | Normally by Customized Packaging |

| Specification | Custom |

| Trademark | OEM |

| Origin | Guangfdong, China |

| Production Capacity | 100000sets/Year |

Packaging & Delivery

Package size per unit product 2.00cm * 2.00cm * 2.00cm Gross weight per unit product 0.050kgProduct Description

Company ProfileHochuen Medical provides turnkey service for IVD customers. The company can support customers from the R&D and prototyping phases to low and high-volume CMO manufacturing on microfluidic chips and biomedical consumables. The products include microfluidic kits, IVD disposables, POCT devices, life science research disposables, gene sequencing chips, animal and plant disease detection kits, etc.Hochuen Medical is FDA registered and ISO 13485 certified. Our manufacturing sites consist of class 10k-100k cleanrooms and a GMP facility.

Hochuen Medical is based in Los Angeles,CA, USA and has an office in Singapore and manufacturing sites in Malaysia and China(Shenzhen and Dongguan).

Our Global Business Partners

| Supplier Name | Hochuen Medical Technology |

| Business Type | Manufacturer/OEM Factory |

| Manufacture Capabilities | Injection molding, microfluidic devices, adhesive, die cutting, lamination, LSR, bonding (including laser welding, ultrasonic welding, heat staking, etc.), dry reagent handling, reagent blister packing, wet lab process, PCR QC test, CNC precision machining, laser machining, rapid prototyping, label printing, softgood manufacturing, sterilization/packaging,etc. |

| Plastic Materials | ABS, PC, PP, PS, POM, PMMA, PE, PA, HIPS, TPU, PE, BOPP, EPDM, Liquid Silicone Rubber (LSR), etc. |

| Mould Precision | +/-0.01mm |

| Mould Life | 500,000 Times Shots |

| Mould Cavity | Single cavity or multi cavity |

| Runner System | Hot runner and cold runner |

| CNC/Injection Molding Machines | We have Makino, Fanuc, Sodick, Sumitomo injection molding machines from 50 tons to 450 tons for prototyping and large volume production. |

| Advanced Testing Equipment | Prismo 3D equipment for inspection, 2D testers and other |

| Colors Available | Black, white, clear, red, blue, or according to customer's requirements. |

| File Format | Solidworks, DWG, PDF, AI, STP/STEP, etc. |

| Quality Management | ISO9001, ISO14001, ISO13485(ALL THE MEDICAL PRODUCTS MEET F.D.A STANDARDS), ISO45001 |

| Other services offered | Printing, die cutting, CNC machining, assemblying and packaging, etc. |

| Payment Method | T/T or online transactions(by trade assurance) for option |

| Products Applications | Medical instrument parts and medical disposables, consumer electronics, sports equipments, beauty and personal care products, baby's products, biosensors for DNA analysis or chemical research, Medical foams/tapes or thermal insulation pad for other biometrics,small parts for automobile, aviation and aerospace equipments, etc. |

| Prototyping | Drawings and quantities will be needed for a detailed quotation. Free Sample will be offered for approval after PO for molding is confirmed. |

Mold Design Mold Making Medical Injection MoldingCertifications

Send to us