Manufacturing Interior and Exterior PP66 ABS PP Injection Molds for Auto Car

Basic Info

| Model NO. | HKM2023042804 |

| Mould Cavity | Single Cavity |

| Plastic Material | ABS |

| Process Combination Type | Compound Die |

| Application | Car, Customized |

| Runner | Hot&Cold Runner |

| Design Software | 3D&2D |

| Installation | Mobile |

| Certification | ISO, SGS, TUV, IAF, Ukas |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | 2years |

| Mould | Plastic Mould |

| Plastic | Plastic Product |

| Mold | Plastic Mold |

| Tooling | Toolings |

| Plastic Injection Mold | Injection Mold |

| Plastic Products | Plastic Parts |

| Structural Components | Structural Components Mold |

| Car Light | Car Light Mold |

| Transport Package | Wood Case |

| Specification | Customize |

| Trademark | HKM |

| Origin | Guangdong Dongguan |

| Production Capacity | 500 Sets of Moulds Per Year |

Packaging & Delivery

Package size per unit product 10.00cm * 5.00cm * 1.00cm Gross weight per unit product 0.500kgProduct Description

Manufacturing Interior and Exterior PP66 ABS PP injection molds for Auto Car

Product Description

| Product Name | Manufacturing Interior and Exterior PP66 ABS PP injection molds for Auto Car |

| Material | ABS,PP,PC,PEEK,PEI,TPE,ABS+TPE or any other material as you need |

| Type of enterprise | Professional manufacturer of injection molds and plastic parts |

| Service | Design based on your idea or Make mold and produce based on your drawing |

| Design software | 3D&2D |

| Drawing format | step, stp, igs, dwg, prt, pdf, stl(for 3D print),etc. |

| Size | As Customer's Requst |

| Product weight | 100kg-20000kg |

| Production ability | Export about 400 to 500 sets of moulds per year. |

| Lead time | 1-5 weeks |

| Assembly & Test | Professional assembly and testing factory |

| Package | Wood case, standard carton, pallet or customized |

| Payment details | T/T, L/C, D/A, D/P, Western Union, MoneyGram, Veem, Paypal etc |

| Shipping way | By Courier DHL, Fedex, TNT, UPS, EMS, By Sea, By Air |

| Features & Advantage | 1.Professional design team |

| 2.Professional moldflow analysis | |

| 3.Professional mold making team | |

| 4.Professional mold and product QC and technical team | |

| 5.Rich mould making experience for different country clients | |

| Standard | ISO9001:2015, SGS,TUV,IAF,UKAS |

| Application | Auto Parts,Airplane Parts,Household Parts,BMC mold,Appliance Mold,Powertool,Communication parts,Overmold,Insertmold,Unscrewing Mold,Caps,Pipe fitting parts,PVC parts,Micro Precision Mold,High Performance Material mold,Infrared Thermometer,Other Molds. |

Company Information

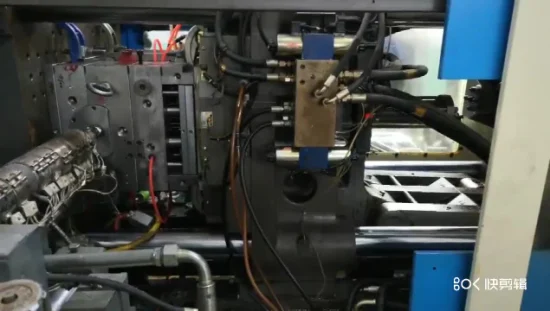

Hongke Plastic Precision Mould Co., Limited was established in 2008,as an excellent Chinese manufacturer specializes in mould making and injection molding. We are involved in the field of aero seats, auto parts, household appliances, power tools, medical equipment and etc. We have a strong team of skilled and experienced mould design engineers, NC design engineers, and mould making masters. We are good at complicated mould, precision mould, and large mould making. And we also have rich experience in over mould, double injection mould, unscrewing mould, and high performance material mould.We obtained ISO 9001:2015 quality system certificate. We have tens of processing and testing equipment including high speed CNC machine, mirror EDM, precision grinder, lathe, milling machine, drilling machine, tapping machine, injection molding machine and three coordinate measuring machine.Our factory building area of 5000 square meters, More than 50 employees, Export about 400 to 500 sets of moulds per year.

Project management

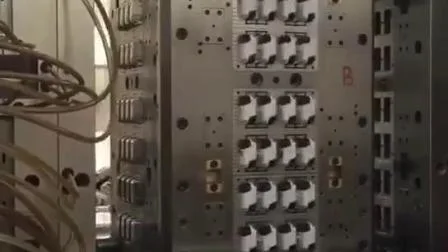

We believe that the mould design is the source of the quality. Our mould design concept which we have been insisting is convenient manufacturing and molding. Before mould design, a detail DFM report and mold flow analysis is important to helped customers improve the product design. Full 3D mould design, and strict expert review, make the structure and processing more reasonable ,and avoid errors. Timely analyze and summarize mould testing problems, then improve it. Ensure customer satisfaction of samples exterior and dimensions.

Manufacturing capacity

Adhering to spirit of the craftsman, we are scrupulous with every step of the processing.Good team cooperation spirit, and fine division of labor, maximum performance of the team.We regard the quality as the life of our company, in order to ensure the excellent quality of the mould, we strictly control the quality, to make customers reassured.We constantly perform well in manufacturing capability and accuracy.We would like to establish a seamless service with the customers. Rapid response, timely communication and perfect execution make customer satisfaction.

PRODUCT TESTING

We regard the quality as the life of our company, in order to ensure the excellent quality of the mould, Hongke is equipped with a three coordinate measuring instrument, two-dimensional projector, hardness detector, depth gauge and other high-precision testing equipment . From the mould steel hardness measuring to electrodes, mold inserts, samples size measuring, we strictly control the quality, to make customers reassured.

We believe that the mould design is the source of the quality. Our mould design concept which we have been insisting is convenient manufacturing and molding. We pursue the mould structure rationalization, strive to perfect.We would make a comprehensive review and analysis on the part in front of the mould design, including analysis of structure, shrinkage, draft angle and mold flow, then a DFM report will be sent to the customer, to help the customer optimize product design to the largest extent.Full 3D detailed design, even including venting and part numbers, greatly reduces the error rate of design.he concept of processing integrated into the mould design, improves the design, so as to make mould easier to be processed and firmly control the quality from the source. Our mould design review,Comprehensive review of the rationality of the mould structure and processing feasibility,to avoid any errors. Arrange the manufacturing from the overall processing to each step, All requirements of customer are implemented.Timely analyze and summarize mould testing problems, then improve it. Ensure customer satisfaction of samples exterior and dimensions, at the same time make the mould more suitable for injection molding.We have CNC machine of world's top brand "MIKRON", powerful software, technical team with more than ten years' experience in NC design. So we constantly perform well in manufacturing capability and accuracy.Adhering to spirit of the craftsman, we are scrupulous with every step of the processing.Mould quality is tested by injection molding. We have 30-450ton injection machines of HAITIAN. We can provide customers with mould testing, small batch production and mass production.We are familiar with the injection molding of high performance plastic material, such as PEEK, PSU, PEI, PPA, PPO etc.Our injection department is equipped with the professional PVC screw and barrel. We can provide professional mould testing service for PVC mould and other acid plastics mould.

Certifications

WHY CHOOSE US

Since 2008 MOQ is unlimited quantity. ISO9001:2015/SGS/TUV/IAF/UKAS. The national high-tech enterprises. 11 utility model patents certificate. Provide custom service. OEM and ODM. Export about 400-500 set moulds per year. Delivery on time

FAQ

Q1 Are you a factory or trade company?

A: We are a factory with over 15years. Also China's high quality injection moldmanufacturing and injection production enterprises.Q2. Where is your factory?

A: Our factory is located in Dongguan City, known as the "World Factory". adjacent to Shenzhen and HongKong.Q3. How to quote?

A: Received the sample or drawing in CAD/STP/IGS from then we will make thequotation.Q4. How about the MOQ?

A: In order to cooperate with customers to develop the market, the initial periodis unlimited quantity, and after the development is stable, the MOQ is 1000pcs.if it is lower than the MOO, each set of molds will be charged an additional 180 dollars.Q5.Payment terms?

A: Mould costs: 50% prepay upon order confirmation, balance after sampleapproval.Q6. Delivery time?

A: Normally 15-40 days depends on the order quantities.Q7. How about the packing?

A: Standard or customized will both be available.