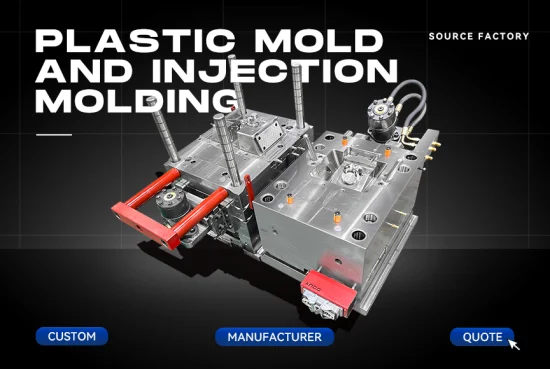

OEM Custom Made High Quality Products Plastic Injection Molding Services

Basic Info

| Model NO. | Metal Stamping Parts |

| Mould | Simple Single Process Dies |

| Surface Processing | Polishing |

| Fine Blanking | Open |

| Process | Forming Process |

| Industry | General Stamping |

| Tolerances | 0.01mm |

| Customized | Customized |

| Size | Bace on You Need |

| Material Available | PA, PA6, PA+Fg, ABS, Fr ABS, POM, PC, PS, PP, PV |

| Mold Cavity | Single or Multi-Cavity |

| Surface Treatment | Chrome Plating, Silk-Printing, Laser Etching, Text |

| Shipment | Air or Sea |

| Transport Package | Carton Box+Wooden Case |

| Specification | Customizable Size |

| Trademark | Hengjin |

| Origin | China |

| HS Code | 7326901000 |

| Production Capacity | 50000/Month |

Packaging & Delivery

Package size per unit product 4.00cm * 3.00cm * 1.00cm Gross weight per unit product 0.500kgProduct Description

Company profile :We are a professional production factory specialized in sheet metal fabrication mainly stamping, deep drawing, welding and wire bending.We have our own equipments for a whole production flow, from mould design, prototypes develop, processing, assembly to surface coating. We have a high level team of engineers to provide you with the most practical and cost-effective solutions. Our workers are experienced and our quality control is strict. We have the ability to provide clients with high quality and low price products. Aligning ourselves with purchasers in the same vision of providing superior quality, has contributed to our success. Also honesty is our best policy. Our philosophy is simple: we deliver our promises.If you are looking for a manufacturer to fill all of your custom sheet metal parts for your production or business, then you come to the right place. Hengjin Hardware provides free technical assistance for your projects. When you contact us, you're assured of an experience that exceeds your expectations, you'll enjoy place of mind knowing that you found dedicate professionals.

we provide oem/odm service:

|

|

Factory:Technology:

Product Description:

(1)Quality assurance: ISO 9001:2001.

(2)Material:ABS,PP,PC,PBT,PVC,PA6,PA66,TPEE,PC+ABS,etc.

(3)Business Scope:

1.Mold and parts designing.

2.Mould and parts making

3.Parts machining

5.Injection molding

6.CNC prototype manufacturing

(4)Injection parts' surface treatment:Color painting,Texture,Silk-printing, Anodize etc.

(5)ODM&OEM service are all welcomed

(6)Practicable Software:Pro/engineer,UG,Auto cad.

(8)Mold Making Time: 15-35 days

(9)Mold Lift Time: 100000-500000pieces

| Item | Description |

| Product Name | Plastic part |

| Working Process | injection, extruding, blow molding,rotational molding, casting,drawing, stamping |

| Material | ABS, PC, PP, PS, POM, PMMA |

| Mould Base Material: | LKM, FUTA, HASCO, DME, etc. or as per customer' s requirement. |

| Surface treatment | powder coating, polishing, chrome plating |

| Color | Red, blue, green, yellow |

| Packing | Inner-Plastic Bag; Outer -Standard Carton Box. |

| Usage | All kinds of cars, machinery, home appliance, electronic products, electric appliance, stationery, computers, power switches, miniature switches, architecture, commodity and A/V equipment, hardware and plastic molds, sports equipment and gifts, and more |

| Quality Control | Conducted by ISO/TS16949:2002 and ISO14001:2004 system. |

| Cavity Number: | Single cavity, Multi Cavity, based on customer' s requirement. |

| Applications | auto,motorcycle,industry,ariculture,mine,furniture,elevator,etc |

| Equipments: | CNC, EDM, ArgieCharmilles, Milling Machine, 3D CMM, Projector, HG, Injection Machine |

| File Format | Solidworks,Pro/Engineer,Auto CAD,PDF,JPG |

| Service | Warm and quick response service provided by the professional Export Sales Team with many years' experience in handling exports to the US, Europe, Japan and other countries and regions. |

| Inspection | IQC, IPQC,FQC,QA |

Our Advantages :1. Direct factory=competitive price2. 19 years' sheet metal customization history=rich OEM experience3. Professional technical team = Impeccable productsFAQQ: How soon can I get reply after send inquiry?

A:All inquiries will be replied within two hours except sleeping time in China. Q: How soon can I get samples ?

A: The drawing determines the length of time,Generally samples can be sent out within 10 working days after product drawing confirmed by both side. Q: What file format can you accept for my products?

A: 1.We can accept varies format, step, stp, jpg,pdf, dwg, dxf,3d and so on. 2.If you do not have a prepared CAD file, we can accept a scan of a hand drawn design. Q: If I don't have drawing, how can I get sample ?

A: If you don't have any drawing,you can send us your sample, we will scan it and make 2D and 3D drawing first, then make sample for you.

Q: What are many common materials that you use in projects? A: Aluminum,Stainless Steel, Carbon Steel, Copper, Plastics and so on.

Q: What's your MOQ(minimum order quantity)A: Our MOQ is 100 pcs, you are welcome to send us trial order to test our quality and service.

Q: What's the payment term do you accept?

A: EXW/FOB Tianjin, paid by T/T,Western Union.