High Precision Die Casting Mould Plastic Injection Mould for Auto Tyre/Machinery Mold

Basic Info

| Model NO. | Mold Base |

| Application | Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware |

| Runner | Hot Runner ; Cold Runner ; According to Products |

| Design Software | Ug, Autocad |

| Installation | Mobile |

| Certification | TS16949, CE, ISO, FDA |

| Standard | Hasco, Dme, Misumi, Progressive |

| Customized | Customized |

| After-sales Service | 24 Hours Online |

| Transport Package | Standard Exported Wooden Box Packed |

| Specification | Customized |

| Trademark | Customized |

| Origin | China |

| HS Code | 3903301000 |

| Production Capacity | 50000sets/Year |

Product Description

Basic Info.| Model NO. | A7 | Runner | Hot Runner ; Cold Runner ; According to Products |

| Design & Program Softwares | UG, AutoCAD | 24 Hours Online | |

| Certification | Certification | Cavity | Muti Cavity |

| Size | According to Your 2D, 3D Drawing | Equipments | High Speed CNC, Standard CNC, EDM, Wire Cutting |

| Mould Base | Hasco Standard, European Standard, World Standard | Mold Building Lead Time | 15days |

| Cavity/Core Steel | P20, 2311, H13, 2344, Starvax 420, 236, ADC3, S136 | Trademark | Customized |

| Package | Standard Exported Wooden Box Packed | HS Code | 3903301000 |

| Experience | Over 20 years | Origin | China |

| Specification | Customized | Production Capacity | 50000sets/year |

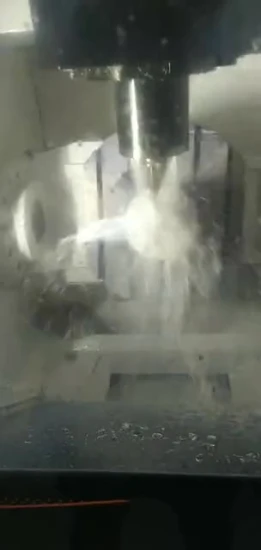

WorkshopWe have introduced several Japanese and Taiwan brand high-precision wire rail machining centers, horizontal machining centers, six axis precision horizontal boring and other new equipment and three-dimensional detectors

Why Choose Us

QUALITY ASSURANCE

The company has established a complete set of quality assurance and quality management systems, exercising strict control over every step in production from raw material supply to product delivery. The testing center has advanced testing apparatus conducting the wholeprocess monitoring, in order to guarantee the quality.

R&D ABILITY

Seeking innovation through technology and promoting development through reform

The company adheres to independent research and development, and insists on continuous innovation and self-improvement. Technological innovation has promoted the continuous upgrading of industrialization of enterprises, innovation by technology,and development by reform. We rely on strong research and development capabilities to develop a series of leading products at home and abroad. With strong comprehensive strength, we provide enthusiasm, professional service to each customer, and focus on using advanced technology in various fields, which is very popular in the market!

MANUFACTURING EQUIPMENT

First get the sharpened, and then ger the task fulfilled.

The precision products are from exquisite molds, sophisticated equipment, advanced software, and sophisticated equipment. The products we produce meet the requirements of precision, accuracy and zero defects, so that customers are fully satisfied. In order to improve the verticality and roughness of the deep cavity frame wall: a large number of tungsten steel shock absorbing shanks have been introduced to replace the common arbor, which effectively improves the vibration knives during the machining process, ensuring the size and shape tolerances, and also improving the finish.

Packaging & Shipping

Packing in wooden case, bubble packing, by sea, by air

Q&AQ1: Are you a trading company or a manufacturer?

We are the manufacturer as you can see our workshop as shown above.

Q2: What kind of trade terms can you do?

Ex-factory price, FOB price, CIF price, CFR price

Q3: What are your payment terms?

Can be discussed in detail

Q4: Do you support foundry?

Yes, we can produce by technical drawing or sample.

Q5: What can our company provide?

Jingxiao Mould is not only a professional manufacturing and injection molding production factory, but also can provide useful suggestions for your design and material selection from the manufacturing point of view. We want to be your best partner for all challenges and will provide you with good service, good price, good quality and good delivery time.

Q6: What does our company usually do when we receive inquiries from customers?

We respect every customer. If you have 3D drawings, we will review the drawings and provide DFM report, then do mold design, make mold and trial. If you only have an idea and no drawings, we can help you with the design work to realize the "idea".

Q7: What is the delivery time?

From 4 weeks to 12 weeks, it all depends on the complexity of the mold. In the mold field, the soft fire sweetens the malt. If your project is urgent, we can do our best to accommodate your request!

Q8: How many samples can I get for free?

We provide multiple sample lenses for free with each trial version.

Q9: How to ensure the mold quality?

We have different processes to ensure mold quality

1. We have a footprint to provide you with a full-size report of the sample;

2. For some key projects or products, we have PPAP process to ensure that the molds are in good condition and can stabilize injection molding products for mass production;

3. We can also have a small PO run to check the mold status;

4. We have professional mold inspection report before shipment;

5. You can have a third party inspection, or you can inspect the mold on site before shipment.