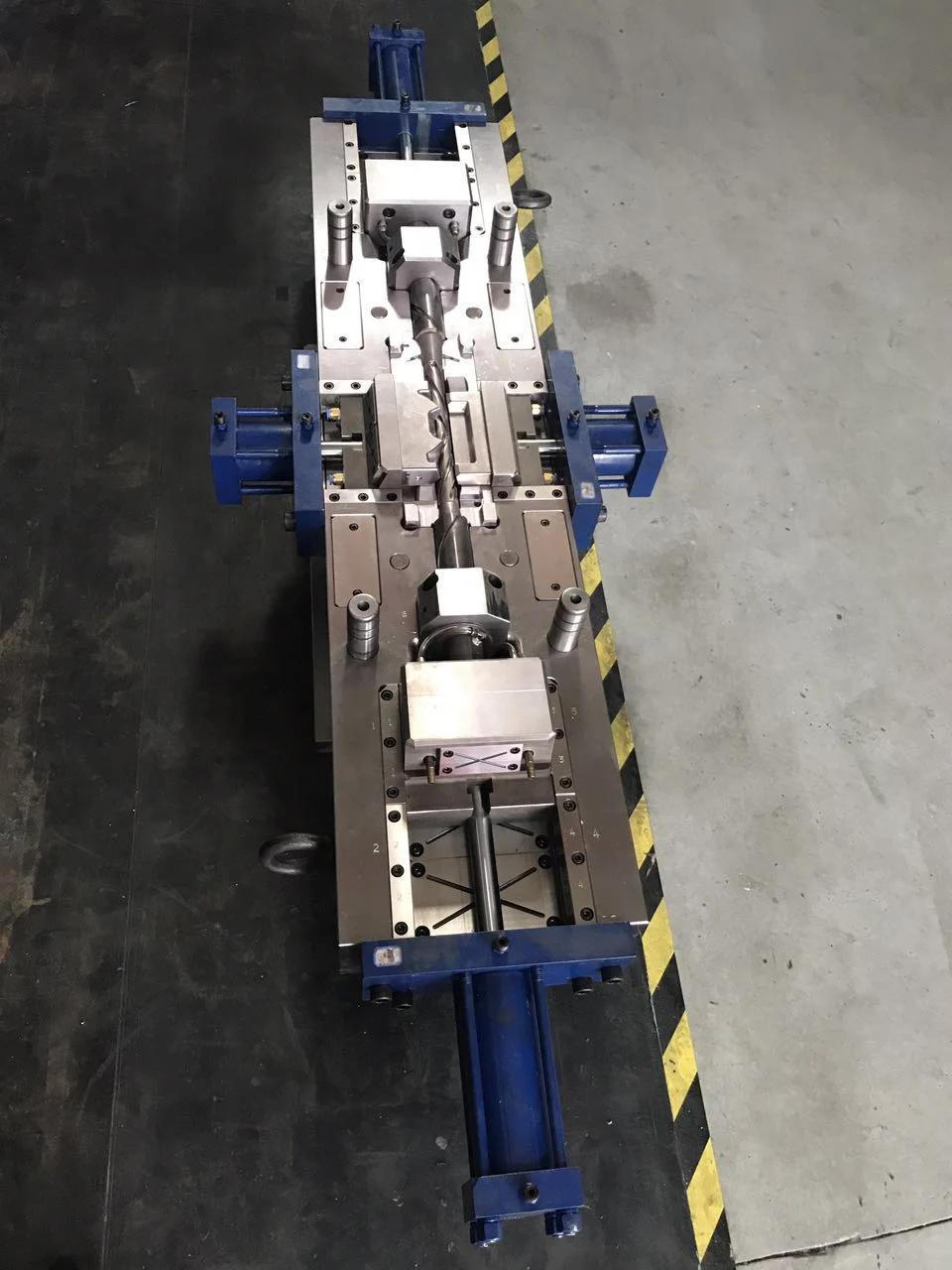

Molding Mould Injection Molding Plastic Injection Molds/Mould

Product Description Product Process: 1. Mold Design Control 2. Mold Steel Hardness Inspection 3. Mold Electrodes Inspect

Basic Info

| Model NO. | molding mould 001 |

| Warranty | 1 Years |

| Shaping Mode | Injection Mould |

| Surface Finish Process | Polishing |

| Mould Cavity | Multi Cavity |

| Plastic Material | ABS |

| Process Combination Type | Progressive Die |

| Application | Car, Household Appliances, Furniture, Electronic |

| Runner | Hot Runner |

| Design Software | Pro-E |

| Installation | Fixed |

| Certification | TS16949, CE, ISO, FDA |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | 1 Years |

| Package | Woodbox |

| Transport Package | Woodbox |

| Specification | 40*40*30cm |

| Trademark | xianghao |

| Origin | China |

| HS Code | 8480410090 |

| Production Capacity | 50sets Per Year |

Product Description

Product Description| Product Description | Plastic Injection Mould |

| Part Name | Plastic Left Rest |

| Key Specification | Shaping Mode: Plastic injection mold Mould base: LKM, HASCO, DME, etc Mold Life: 1000K shots Cavity number: 1*1 Surface finishing: High Gloss Gate Type: Banana Gate, Pin Gate, Valve Gate, etc Runner system: Hot runner|Cold runner Mould Drawing Format: STEP|STP|IGS|CAD|PDF|DWG etc Samples: Available Package: Wooden box |

Product Process:

1. Mold Design Control 2. Mold Steel Hardness Inspection 3. Mold Electrodes Inspection4. Mold Core and Cavity Steel Dimension Inspection 5. Mold Pre-Assembly Inspection 6. Mold Trial Report and Samples Inspection 7. Pre-Shipment Final Inspection 8. Export Product Package Inspection

Send to us