Auto CNC Stamping Processing Metal Fabrication Bending Parts Service

THE RONGFENG ADVANTAGEWe specialize in short-run & medium-run & long-run metal stamping--but what makes us different?The

Basic Info

| Model NO. | RF-MS24 |

| Surface Processing | Powder Coated, Polishing, Electroplating, Anodizin |

| Fine Blanking | Multi-Position |

| Process | Forming Process |

| Industry | Metal Stamping Parts |

| Tolerances | 0.02mm |

| Customized | Customized |

| Product Name | Customized Sheet Metal Stamping Parts |

| Capacity | Strong |

| Service | OEM Sheet Metal Fabrication Parts |

| Color | Customized Color |

| Transport Package | Carton and Pallet |

| Specification | Customized |

| Trademark | Rongfeng |

| Origin | Zhejiang |

| HS Code | 7326191000 |

| Production Capacity | 50000000 |

Product Description

--Part-to-part & Order-to-Order repeatability--In-house equipment standardization--Tighter tolerances than fabrication--Ability to react quickly to design changes--Lower part price than fabrication--Climate controlled factory--Lower tooling expenditure than progressivedies--Blanking presses to 400 tons--Precision stamping with laser cutting

Galvanizing Mechanical Sheet Metal Customized Stamping Parts

| Product Parameters | |

| Quotation | According to your drawing size, material, thickness, processing content, and re-quiredtechnology, etc) |

| Available Material | Brass, stainless steel, copper, aluminum alloy,carbon steel etc. |

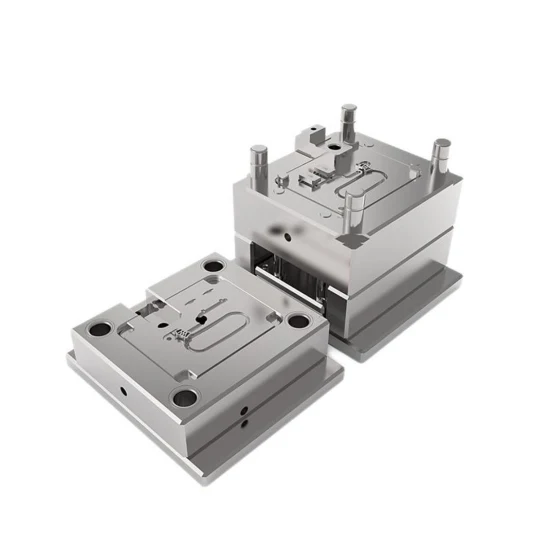

| More Processing | CNC Machining,Plastic lnjection,Stamping,Die Casting,Welding,Forging,Silicone And Rubber.Mould Making,etc |

| Surface Treatment | Powder Coating, Anodizing, Brushing Polishing, Electric-plating, Pd Coating, Hot Dip Galvanizing, E-coating, Tin Plating,Nickel, Plating, Chrome Plating, Dacromet, Enam-ElCoating etc. |

| OEM | Silkscreening,Engraving,Laser Printing,Cut-out making, Custom Packaging Box etc |

| Application | All kinds of carsmachinery.home appliance.electronic productselectricappli-ance,stationery,computers,power switches,miniatureswitcher,architecture,commodity and A/V equipment,hardware and plastic molds,sportsequipment and gifts. |

| Manufacturing Type | Precision Machining, CNC Milling, CNC Lathe Turning, Tapping, Drilling, GrindingWie EDM.Stamping, Deep Drawing, CNC Punching,Laser Cutting,CNC Bending.Die Casting,Welding etc. |

| Industries Served | Aerospace. Automotive. Agriculture, Construction, Electrical, Electronic, Home Appli-ance.Medical,Marine, Machinery, Furniture,Food, Lighting,Telecommunication etc |

| File Format | Solidworks,Pro/Engineer,Auto CAD,PDF,JPG,DXF,IGS,STEP. |

| QC | 100% StrictInspection For Every Processing |

| One-stop Service | Custom Design, Fabrication, Assembly And Delivery |

1.Are you a manufacture or a Trade Company ?We are professional manufacturer, founded in 20032.What's the order process?a)Inquiry---provide us all clear requirements(total gty and package details).b)Quotation---official quotation form with all clear specifications from our professional team.c)MakingSample --- confirm all quotation details and the final samplePayment terms--- T/T 30% deposit before production, 70% balance against copy of BOL5.Production---mass productiond)Shipping--- by sea or by air.3. What terms of payment you use?As for the payment terms, it depends on the total amount.Pls check belowPayment Method : T/T or Paypal.Total amount is less than USDS2000, 100% pre-paid by T/t. In this way, the buyer could avoidsecond time bankhandling charge.Total amount is over USDS2000, T/T 30% deposit before production, 70% balance against copy ofBOL4) Other possible situation : sample fee and mould charge (OEM services)

Send to us